First manufacture of red LEDs: In 1968, Monsanto became the first company to start mass production of the first type of light emitting diode (LED), using the in-house production of gal·liun arsenide. This date marked the beginning of the era of the actual LED used for lighting, although at the beginning they were of very low intensity. From 1968 to 1970, sales were doubled every few months. Their products (discrete LEDs and digital displays with seven segments) became the industry standards. The main markets were electronic calculators, digital clocks and other types of applications with digital display. Monsanto became a pioneer in the field of optoelectronics during the 1970s, and later on has transferred the business to HP.

HISTORY

Although the first visible light emitting LEDs were made in 1962 by the group of Nick Holonyak at General Electric, these early devices were not particularly successful from the commercial perspective in view of their extremely high cost. GE pitched its selling price at an astronomical $260 per piece, and as such they remained more of a lab curiosity rather than finding commercial applications.

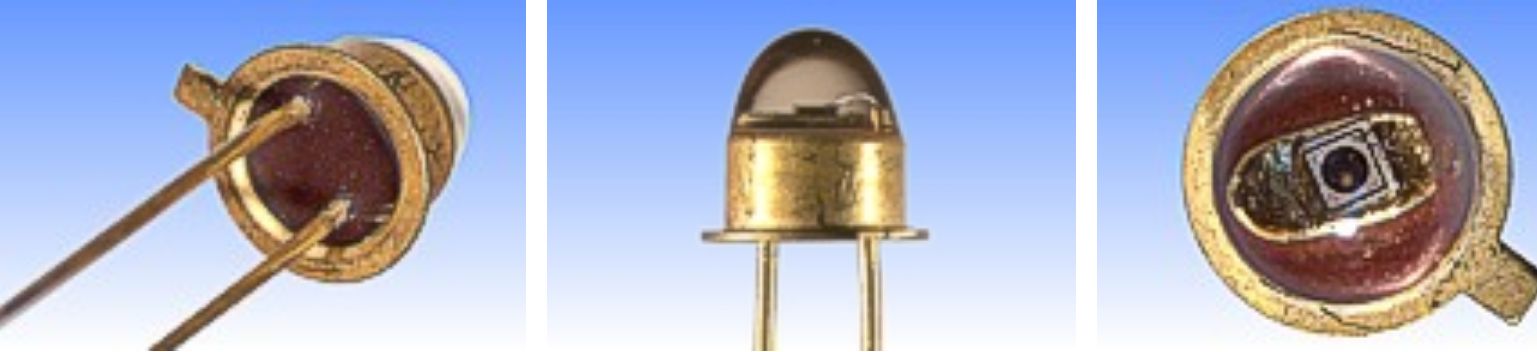

This situation changed in 1968 when Monsanto, the manufacturer of the raw Gallium Arsenide Phosphide semiconductor material, established its own high volume production of both alphanumeric displays as well as discrete LED lamps. The type MV1 featured on this page was the first of the company's solid state lamps, and is widely regarded as being the world's first commercial visible light LED.

The heart of the device is the semiconducting die, which consists of a GaAs substrate having a GaAsP top layer which forms the light emitting component. This layer was applied by the vapour phase epitaxy process developed at GE. Electrical connection to the lower side of the die is effected by its direct contact with the gold plated anvil shaped formation at the inner end of the cathode lead. The upper side of the die is provided with a metallised contact, probably of an inert metal such as platinum or rhodium, featuring a hole at its centre through which light is emitted. Current to the metallisation is carried via a fine wire of colourless metal, suspected to be platinum, which is welded to the anode lead. The assembly is packaged in a standard TO-5 header normally employed for transistors of the era, and sealed with a clear acrylic dome of high refractive index which aids light extraction and protects the die.

| Manufacturer: | Monsanto | |

| Lamp Voltage: | 1.65 Volts | |

| Lamp Current: | 20 mA Nominal | 50 mA Maximum |

| Lamp Power: | 33 mW Nominal | 83 mW Maximum |

| Cap Type: | Gold Plated Wires | √ė 0.0175" x 0.1" Pitch |

| Bulb Type: | TO-5 transistor | |

| Bulb Finish: | Clear acrylic | |

| Die Chemistry: | GaAsP | |

| Luminous Flux: | ||

| Luminous Efficacy: | ||

| Peak Intensity: | 0.5 millicandela | |

| Beam Distribution: | 120 degrees | to half-peak |

| Peak Wavelength: | 655 nm | |

| Colour Temperature & CRI: | CCT: N/A | CRI: N/A |

| Chromaticity Co-ordinates: | CCx: 0.721 | CCy: 0.278 |

| Rated Lifetime: | ||

| Burning Position: | Universal | |

| Overall Length: | ||

| Light Centre Length: | ||

| Factory: | Palo Alto, CA | U.S.A. |

| Date of Manufacture: | Circa 1970 | |

| Original / Present Value: | GB £1.00 (1969) | GB £12.30 (2008) |

| References: | 1) Vintage Technology Association, Discrete LEDs Page |

| 2) The LED Museum, 1960s Exhibits | |

| 3) EE Times "LEDs Cast Monsanto in Unfamiliar Role", September 1997 ____________________________________________________________ |

|

In spite of itself, Monsanto introduced the first commercial LED display. Monsanto really wasn't interested in electronic devices. It wanted to sell raw materials. So it developed a friendly collaboration with Hewlett-Packard Co., expecting that HP would make light-emitting diodes and LED displays while Monsanto would provide the raw material-the gallium arsenide phosphide. Monsanto was creating a customer.

In the mid-1960s, Monsanto sent a scientist, Arno Herzog, from St. Louis to California to help HP develop an LED and LED-display business using Monsanto's GaAsP.

But HP was nervous about depending on a single source. And when Monsanto started a test-equipment division in the mid-1960s under Fred Katzmann, formerly the general manager of scope manufacturer DuMont, HP felt that Monsanto might eventually have a conflict of interest. Monsanto believed its instrument business would never appear on HP's screen (though Katzmann privately hoped he might someday overtake HP).

So the informal relationship was severed. HP started growing gallium arsenide phosphide while continuing to purchase GaAsP from Monsanto. And Monsanto started its Electronic Special Products Division, making LEDs and LED displays, largely under the influence of a Monsanto salesman, George MacLeod.

But whatever got Monsanto interested in LEDs in the first place? Before the display business started, there was a business-a small and expensive business-in LED lamps. For the ori gin of LED lamps, all fingers point to Nick Holonyak Jr., a remarkable man whose own fingers reached into a wide range of semiconductor developments.

When he wasn't getting a bit of exercise by walking across a gym floor on his hands or climbing 20-foot ropes (both of which he quit doing when he reached the age of 60 because his shoulder began bothering him), Holonyak worked on light-emitting diodes, LED materials and processes, semiconductor lasers, tunnel diodes, transistors, pnpn switches and silicon-controlled rectifiers. He created the triac version of the SCR, the heart of all dimmer switches. For his pioneering work in lasers and LEDs, Holonyak won the Japan Prize, Japan's highest scientific award.

Long collaboration

That was just one of a host of awards and honors heaped on Holonyak, including election to the Academy of Sciences, since he received his doctorate in electrical engineering at the University of Illinois at Urbana in 1954. He did his graduate work there as the first student of John Bardeen, fresh from Bell Telephone Laboratories in 1951, three years after Bardeen and Walter Brattain announced their invention of the transistor. Bardeen started a semiconductor lab at the university in 1952, with Holonyak and some post-docs. This began a 40-year friendship and collaboration.

Holonyak left the University of Illinois (to return in 1963 as a professor) in 1954 to join Bell Labs, where he helped demonstrate the feasibility of diffused-impurity silicon devices, a seminal contribution. He left Bell Labs at the invitation of his draft board and worked for the U.S. Army Signal Corps from 1955 to 1957. In 1957, he joined the General Electric Co. in Syracuse, N.Y. And that's when he really got busy.

He started at GE as a physicist, then moved up to become unit manager, then manager of the Advanced Semiconductor Laboratory. He contributed to the development of power and signal pnpn devices, tunnel diodes, the epitaxial growth of III-V compounds (materials from the third and fi fth columns of the periodic table of elements), junction luminescence and semiconductor lasers.

LED set the stage

In 1960, Holonyak developed the first GaAsP pn junction. Within two years, he had developed semiconductor lasers, visible-light semiconductor lasers and, in 1962, he invented the first practical light-emitting diode, which GE commercialized and which set the stage for the use of III-V alloys in many semiconductor devices.

Light emission from pn junctions had been noted as early as 1932, but wasn't pursued. In the early 1960s, there was intensive exploration of light-emitting junctions at Bell Labs and, in Europe, at Philips and Siemens. Siemens, in fact, like Bell Labs, was probably working on III-V materials as far back as the 1950s.

Holonyak was first to make alloy III-V materials by vapor-phase epitaxy and first to make an LED out of an alloy. Holonyak developed GaAsP as the material for LEDs, while Bell Labs researchers rejected the modification of GaAs with phospho rous because they felt it would spoil GaAs properties.

Since there was no real market for light-emitting semiconductors, GE's pricing was rather arbitrary, but not completely. Texas Instruments Inc. introduced a GaAs infrared emitter and priced it arbitrarily at $130. GE had a GaAs laser, developed by Bob Hall at the company's Schenectady, N.Y., research lab. GE figured that a laser is worth more than a mere infrared emitter, so GE priced its GaAs laser at $1,300.

GE further believed that a visible red GaAsP laser, since it was a visible-spectrum device (from Holonyak's lab), was worth twice as much-$2,600. As for an IR-emitting diode, TI had one for $130, so GE figured the visible-spectrum device was worth more and priced its red LED at $260. And it soon appeared in the Allied Radio catalog.

At those prices, early LEDs didn't produce a big market. They also didn't produce a great deal of light. But several companies could see a future with them. One of them was Monsanto, whose people saw a future market for GaAsP. Monsanto sent several people to visit Holonyak at GE and came away with the decision to get the LED business going.

But it didn't really get to be a serious business until the late 1960s and early 1970s, when calculators, then wristwatches, began to consume LED displays. By then, Monsanto was fully in the device business. It was in the 1965-66 period that the company's California salesman, George MacLeod, convinced Monsanto that it could boost profit margins tenfold if it started making devices as well as the GaAsP material. In late 1967, MacLeod took over the company's LED research group and, in September 1968, the company set up a factory in Palo Alto, Calif., MacLeod's territory.

In 1968-1970, sales were skyrocketing, doubling every few months for a while. There was a brief setback when one of the original engineers from St. Louis, Bruce Blakkan, left to start his own company, Litronix. In 1971, George MacLeod was appointed general manager of Monsanto's optoelectronics operatio n, a position he held till 1975.

For several years, from the late 1960s to the mid-1970s, the hot competition was in numeric displays, driven at first by calculators, then by wristwatches, following Hamilton Watch Co.'s introduction of the Pulsar digital watch in 1972. For a while, the early contenders, Monsanto and HP, took turns leaping into first place with a more advanced multiple-numeric or alphanumeric LED displays.

Monsanto came out with the first commercial numeric display, the MAN-1A (the "MAN" for Monsanto alphanumeric). This was a seven-segment numeric display comprising 14 discrete GaAsP chips mounted on a substrate, two chips to a segment. The alphanumeric designation was a bit optimistic, based on the fact that several numerics looked like letters. The 5, as one example, could be used as an S.

Expanded field

Then HP introduced a 5 x 7 matrix, 28-dot LED display with an on-board BCD (binary-coded decimal) decoder/driver. Litronix, a spin-off of Monsanto, topped that in 1977 with an intelligent LED display, which included both column and row drivers, ROM-resident characters and direct decoding from ASCII inputs.

Others joined the fray, including Texas Instruments, Motorola, Fairchild, National Semiconductor and, in fact, many other semiconductor companies. Not content with supplying LEDs for the fast-growing digital-watch business, many semiconductor companies started manufacturing watches themselves. Leading business thinkers wrote learned articles about the economic wisdom of vertical integration into the watch and other businesses that use semiconductors.

Traditional watch manufacturers warned the semiconductor companies that watches were a jewelry business, of which semiconductor people were supremely ignorant. With an arrogance that was common then, the semiconductor manufacturers sallied forth and almost choked on watches. Litronix, the supplier of LED displays for the Hamilton Pulsar line, was so weakened by its foray into its own watch business that Siemens, which had purchased 25 percent of the company in the mid-1970s, was able to buy control of the company in 1979 at a bargain price.

While the major developments from the mid-1960s to the mid-1970s appeared to center on LED numeric and alphanumeric displays, there was intense but quieter activity in discrete LED lamps.

The early LEDs were inefficient at converting electric current to visible light. They were acceptable for panel-lamp indicators and displays, where high brightness wasn't important. But now there were efforts to boost efficiency and light output. The activity had a twofold objective-producing visible light more efficiently, even more efficiently than incandescents, and producing more colors. Those activities succeeded.

Work at Bell Labs in the 1960s showed that adding impurity dopants, especially nitrogen, to gallium phosphide could boost light-output efficiency, making for brighter green LEDs. In fact, most green LEDs today are nitrogen-doped gallium phosphide, and the red ones are nitrogen-doped gallium-arsenide phosphide.

One of Holonyak's doctoral students at the University of Illinois was George Craford, who joined Monsanto in 1967 as a research physicist. During the early 1970s, Craford and his team at Monsanto were working on a version of GaAsP, modified by nitrogen. That led to the first yellow and to improved red LEDs. Bell Labs produced greens with nitrogen-doped gallium phosphide using liquid-phase epitaxy. Monsanto, using vapor-phase epitaxy, an extension of Holonyak's work, made orange and high-brightness red.

Marketing sees red

Marketing sees red

This effort didn't go very far at first, because Monsanto's marketing department reported that the only color customers wanted was red. Customers used red displays for calculators, so their only concern was getting cheaper LEDs. Marketing never considered other LED applications. Its conclusion that red was the only color wanted may have stemm ed from asking the wrong question or asking the wrong people.

During Craford's later days at Monsanto, Holonyak, as a consultant to the company, urged him to try indium-gallium phosphide for shorter wavelengths. This was a demonstrated laser material in Holonyak's lab. Monsanto blocked the effort because, by the late 1970s, it was about to sell its optoelectronics business to General Instrument, which it did in 1979. That's when Craford joined Hewlett-Packard, where he is now R&D manager for materials technology at the Optoelectronics Division.

By the early 1980s, everybody was intent on getting extra colors and extra brightness. And they did. Aluminum gallium arsenide yielded high-brightness red. Aluminum indium gallium phosphide (achieved by aluminum-gallium substitution) gave red and amber. Nitride combinations have recently yielded high-brightness green and blue, though blues were and are weaker than other colors.

In today's commercial red LEDs, one can achieve 10 to 20 lumens per watt. T hat compares favorably with the 15 to 17 lumens/ W delivered by a conventional incandescent light bulb, Craford at HP and Frank Kenter, international marketing manager at Siemens, point out.

But in an application like an automobile taillight or brake light, if you use a bare incandescent, you need a red lens. And that throws away all the blue and green, so you retain only about three or four red lumens per watt. Today, LEDs, especially bright-red LEDs, are used in applications that were probably unthinkable 30 years ago.

In Cupertino, Calif., there are LED-based red traffic lights. A red traffic signal uses about 500 LEDs at a cost of about $200. That competes favorably with an incandescent at about $2.50, because the LED signal consumes about 25 percent of the power and requires far less maintenance than incandescents. The payback period is estimated at about three years.

In Cupertino, Calif., there are LED-based red traffic lights. A red traffic signal uses about 500 LEDs at a cost of about $200. That competes favorably with an incandescent at about $2.50, because the LED signal consumes about 25 percent of the power and requires far less maintenance than incandescents. The payback period is estimated at about three years.

Further boosts in red-LED efficiency ma y reduce the number of LEDs needed in a traffic light to 100 or so, making it possible to save $1,000 per intersection per year. There are also high-brightness yellows based on gallium aluminum indium phosphide. But the payback period is longer because the "on" time of a yellow traffic light is shorter than that of red.

Brighter LEDs are now going after markets that were unthinkable in the early days. These include outdoor applications like automobile brake lights and taillights, outdoor signs, obstruction lighting, radio-transmitter towers and airport runways.

Automobiles already constitute a major market for high-brightness LEDs, in some cases resulting from styling pressures. In one case, Ford wanted a high-mount brake light in the spoiler of the sporty Taurus SHO. The spoiler wasn't thick enough to house a regular incandescent assembly without ruining the aesthetics of the design. Further, the spoiler had a vibration period that would have destroyed the filaments in standard incandescents. In addi tion, a study at the University of Michigan indicated that the faster rise time of LEDs in brake lights could alert drivers more quickly and thus reduce accidents at highway speeds.

Beyond those considerations, many automobiles are getting close to the edge in power consumption. The use of high-efficiency LEDs can obviate a requirement for a larger storage battery. And on a system basis, according to LED manufacturers, the total cost of LEDs in cars can actually be lower than that of incandescents-when one considers the cost of cutting out metal to install an incandescent assembly, the cost of a required reflector and red lens, and the warranty costs of replacing blown-filament incandescents.

So, while most LED sales volume is still in low-cost GaAsP, the action lies in high-profit, high-brightness LEDs and in colors not available three decades ago.

Monsanto leaves

Missing from today's action is one of the pioneers in the business, Monsanto. In 1979, perhaps tiring of a business that w as so different from the mature-business traditions of the Midwest, Monsanto sold its optoelectronics operation to General Instrument. In that year, MacLeod retired and went into the important business of growing wine grapes, which he does to this day.

General Instrument hired Ralph Simon as general manager of its new optoelectronics business. Simon left during the economic slump of 1984 and, in 1987, GI sold the operation to two private investors who had little experience in this type of business. They changed the company name to Quality Technology and ran it for two years, then got in arrears on interest payments.

GI came back into the picture and, in December 1989, brought back Simon as chief executive. Simon and some new investors bought out General Instrument, then later acquired Philips Optoelectronics and Harris Optoelectronics, which had been GE Optoelectronics, the pioneer in the optoelectronics business. In 1995, feeling that the name Quality Technology gave no clue as to its business, the company changed its name to QT Optoelectronics.

And everybody is marching forward to more colorful and brighter days.

I n spite of itself, Monsanto introduced the first commercial LED display. Monsanto really wasn't interested in electronic devices. It wanted to sell raw materials. So it developed a friendly collaboration with Hewlett-Packard Co., expecting that HP would make light-emitting diodes and LED displays while Monsanto would provide the raw material-the gallium arsenide phosphide. Monsanto was creating a customer.

In the mid-1960s, Monsanto sent a scienti st, Arno Herzog, from St. Louis to California to help HP develop an LED and LED-display business using Monsanto's GaAsP.

But HP was nervous about depending on a single source. And when Monsanto started a test-equipment division in the mid-1960s under Fred Katzmann, formerly the general manager of scope manufacturer DuMont, HP felt that Monsanto might eventually have a conflict of interest. Monsanto believed its instrument business would never appear on HP's screen (though Katzmann privately hoped he might someday overtake HP).

So the informal relationship was severed. HP started growing gallium arsenide phosphide while continuing to purchase GaAsP from Monsanto. And Monsanto started its Electronic Special Products Division, making LEDs and LED displays, largely under the influence of a Monsanto salesman, George MacLeod.

But whatever got Monsanto interested in LEDs in the first place? Before the display business started, there was a business-a small and expensive business-in LED lamps. For the ori gin of LED lamps, all fingers point to Nick Holonyak Jr., a remarkable man whose own fingers reached into a wide range of semiconductor developments.

When he wasn't getting a bit of exercise by walking across a gym floor on his hands or climbing 20-foot ropes (both of which he quit doing when he reached the age of 60 because his shoulder began bothering him), Holonyak worked on light-emitting diodes, LED materials and processes, semiconductor lasers, tunnel diodes, transistors, pnpn switches and silicon-controlled rectifiers. He created the triac version of the SCR, the heart of all dimmer switches. For his pioneering work in lasers and LEDs, Holonyak won the Japan Prize, Japan's highest scientific award.

Long collaboration

That was just one of a host of awards and honors heaped on Holonyak, including election to the Academy of Sciences, since he received his doctorate in electrical engineering at the University of Illinois at Urbana in 1954. He did his graduate work there as the first student of John Bardeen, fresh from Bell Telephone Laboratories in 1951, three years after Bardeen and Walter Brattain announced their invention of the transistor. Bardeen started a semiconductor lab at the university in 1952, with Holonyak and some post-docs. This began a 40-year friendship and collaboration.

Holonyak left the University of Illinois (to return in 1963 as a professor) in 1954 to join Bell Labs, where he helped demonstrate the feasibility of diffused-impurity silicon devices, a seminal contribution. He left Bell Labs at the invitation of his draft board and worked for the U.S. Army Signal Corps from 1955 to 1957. In 1957, he joined the General Electric Co. in Syracuse, N.Y. And that's when he really got busy.

He started at GE as a physicist, then moved up to become unit manager, then manager of the Advanced Semiconductor Laboratory. He contributed to the development of power and signal pnpn devices, tunnel diodes, the epitaxial growth of III-V compounds (materials from the third and fi fth columns of the periodic table of elements), junction luminescence and semiconductor lasers.

LED set the stage

In 1960, Holonyak developed the first GaAsP pn junction. Within two years, he had developed semiconductor lasers, visible-light semiconductor lasers and, in 1962, he invented the first practical light-emitting diode, which GE commercialized and which set the stage for the use of III-V alloys in many semiconductor devices.

Light emission from pn junctions had been noted as early as 1932, but wasn't pursued. In the early 1960s, there was intensive exploration of light-emitting junctions at Bell Labs and, in Europe, at Philips and Siemens. Siemens, in fact, like Bell Labs, was probably working on III-V materials as far back as the 1950s.

Holonyak was first to make alloy III-V materials by vapor-phase epitaxy and first to make an LED out of an alloy. Holonyak developed GaAsP as the material for LEDs, while Bell Labs researchers rejected the modification of GaAs with phospho rous because they felt it would spoil GaAs properties.

Since there was no real market for light-emitting semiconductors, GE's pricing was rather arbitrary, but not completely. Texas Instruments Inc. introduced a GaAs infrared emitter and priced it arbitrarily at $130. GE had a GaAs laser, developed by Bob Hall at the company's Schenectady, N.Y., research lab. GE figured that a laser is worth more than a mere infrared emitter, so GE priced its GaAs laser at $1,300.

GE further believed that a visible red GaAsP laser, since it was a visible-spectrum device (from Holonyak's lab), was worth twice as much-$2,600. As for an IR-emitting diode, TI had one for $130, so GE figured the visible-spectrum device was worth more and priced its red LED at $260. And it soon appeared in the Allied Radio catalog.

At those prices, early LEDs didn't produce a big market. They also didn't produce a great deal of light. But several companies could see a future with them. One of them was Monsanto, whose people saw a future market for GaAsP. Monsanto sent several people to visit Holonyak at GE and came away with the decision to get the LED business going.

But it didn't really get to be a serious business until the late 1960s and early 1970s, when calculators, then wristwatches, began to consume LED displays. By then, Monsanto was fully in the device business. It was in the 1965-66 period that the company's California salesman, George MacLeod, convinced Monsanto that it could boost profit margins tenfold if it started making devices as well as the GaAsP material. In late 1967, MacLeod took over the company's LED research group and, in September 1968, the company set up a factory in Palo Alto, Calif., MacLeod's territory.

In 1968-1970, sales were skyrocketing, doubling every few months for a while. There was a brief setback when one of the original engineers from St. Louis, Bruce Blakkan, left to start his own company, Litronix. In 1971, George MacLeod was appointed general manager of Monsanto's optoelectronics operatio n, a position he held till 1975.

For several years, from the late 1960s to the mid-1970s, the hot competition was in numeric displays, driven at first by calculators, then by wristwatches, following Hamilton Watch Co.'s introduction of the Pulsar digital watch in 1972. For a while, the early contenders, Monsanto and HP, took turns leaping into first place with a more advanced multiple-numeric or alphanumeric LED displays.

Monsanto came out with the first commercial numeric display, the MAN-1A (the "MAN" for Monsanto alphanumeric). This was a seven-segment numeric display comprising 14 discrete GaAsP chips mounted on a substrate, two chips to a segment. The alphanumeric designation was a bit optimistic, based on the fact that several numerics looked like letters. The 5, as one example, could be used as an S.

Expanded field

Then HP introduced a 5 x 7 matrix, 28-dot LED display with an on-board BCD (binary-coded decimal) decoder/driver. Litronix, a spin-off of Monsanto, topped that in 1977 with an intelligent LED display, which included both column and row drivers, ROM-resident characters and direct decoding from ASCII inputs.

Others joined the fray, including Texas Instruments, Motorola, Fairchild, National Semiconductor and, in fact, many other semiconductor companies. Not content with supplying LEDs for the fast-growing digital-watch business, many semiconductor companies started manufacturing watches themselves. Leading business thinkers wrote learned articles about the economic wisdom of vertical integration into the watch and other businesses that use semiconductors.

Traditional watch manufacturers warned the semiconductor companies that watches were a jewelry business, of which semiconductor people were supremely ignorant. With an arrogance that was common then, the semiconductor manufacturers sallied forth and almost choked on watches. Litronix, the supplier of LED displays for the Hamilton Pulsar line, was so weakened by its foray into its own watch business that Siemens, which had purchased 25 percent of the company in the mid-1970s, was able to buy control of the company in 1979 at a bargain price.

While the major developments from the mid-1960s to the mid-1970s appeared to center on LED numeric and alphanumeric displays, there was intense but quieter activity in discrete LED lamps.

The early LEDs were inefficient at converting electric current to visible light. They were acceptable for panel-lamp indicators and displays, where high brightness wasn't important. But now there were efforts to boost efficiency and light output. The activity had a twofold objective-producing visible light more efficiently, even more efficiently than incandescents, and producing more colors. Those activities succeeded.

Work at Bell Labs in the 1960s showed that adding impurity dopants, especially nitrogen, to gallium phosphide could boost light-output efficiency, making for brighter green LEDs. In fact, most green LEDs today are nitrogen-doped gallium phosphide, and the red ones are nitrogen-doped gallium-arsenide phosphide.

One of Holonyak's doctoral students at the University of Illinois was George Craford, who joined Monsanto in 1967 as a research physicist. During the early 1970s, Craford and his team at Monsanto were working on a version of GaAsP, modified by nitrogen. That led to the first yellow and to improved red LEDs. Bell Labs produced greens with nitrogen-doped gallium phosphide using liquid-phase epitaxy. Monsanto, using vapor-phase epitaxy, an extension of Holonyak's work, made orange and high-brightness red.

Marketing sees red

Marketing sees red

This effort didn't go very far at first, because Monsanto's marketing department reported that the only color customers wanted was red. Customers used red displays for calculators, so their only concern was getting cheaper LEDs. Marketing never considered other LED applications. Its conclusion that red was the only color wanted may have stemm ed from asking the wrong question or asking the wrong people.

During Craford's later days at Monsanto, Holonyak, as a consultant to the company, urged him to try indium-gallium phosphide for shorter wavelengths. This was a demonstrated laser material in Holonyak's lab. Monsanto blocked the effort because, by the late 1970s, it was about to sell its optoelectronics business to General Instrument, which it did in 1979. That's when Craford joined Hewlett-Packard, where he is now R&D manager for materials technology at the Optoelectronics Division.

By the early 1980s, everybody was intent on getting extra colors and extra brightness. And they did. Aluminum gallium arsenide yielded high-brightness red. Aluminum indium gallium phosphide (achieved by aluminum-gallium substitution) gave red and amber. Nitride combinations have recently yielded high-brightness green and blue, though blues were and are weaker than other colors.

In today's commercial red LEDs, one can achieve 10 to 20 lumens per watt. T hat compares favorably with the 15 to 17 lumens/ W delivered by a conventional incandescent light bulb, Craford at HP and Frank Kenter, international marketing manager at Siemens, point out.

But in an application like an automobile taillight or brake light, if you use a bare incandescent, you need a red lens. And that throws away all the blue and green, so you retain only about three or four red lumens per watt. Today, LEDs, especially bright-red LEDs, are used in applications that were probably unthinkable 30 years ago.

In Cupertino, Calif., there are LED-based red traffic lights. A red traffic signal uses about 500 LEDs at a cost of about $200. That competes favorably with an incandescent at about $2.50, because the LED signal consumes about 25 percent of the power and requires far less maintenance than incandescents. The payback period is estimated at about three years.

In Cupertino, Calif., there are LED-based red traffic lights. A red traffic signal uses about 500 LEDs at a cost of about $200. That competes favorably with an incandescent at about $2.50, because the LED signal consumes about 25 percent of the power and requires far less maintenance than incandescents. The payback period is estimated at about three years.

Further boosts in red-LED efficiency ma y reduce the number of LEDs needed in a traffic light to 100 or so, making it possible to save $1,000 per intersection per year. There are also high-brightness yellows based on gallium aluminum indium phosphide. But the payback period is longer because the "on" time of a yellow traffic light is shorter than that of red.

Brighter LEDs are now going after markets that were unthinkable in the early days. These include outdoor applications like automobile brake lights and taillights, outdoor signs, obstruction lighting, radio-transmitter towers and airport runways.

Automobiles already constitute a major market for high-brightness LEDs, in some cases resulting from styling pressures. In one case, Ford wanted a high-mount brake light in the spoiler of the sporty Taurus SHO. The spoiler wasn't thick enough to house a regular incandescent assembly without ruining the aesthetics of the design. Further, the spoiler had a vibration period that would have destroyed the filaments in standard incandescents. In addi tion, a study at the University of Michigan indicated that the faster rise time of LEDs in brake lights could alert drivers more quickly and thus reduce accidents at highway speeds.

Beyond those considerations, many automobiles are getting close to the edge in power consumption. The use of high-efficiency LEDs can obviate a requirement for a larger storage battery. And on a system basis, according to LED manufacturers, the total cost of LEDs in cars can actually be lower than that of incandescents-when one considers the cost of cutting out metal to install an incandescent assembly, the cost of a required reflector and red lens, and the warranty costs of replacing blown-filament incandescents.

So, while most LED sales volume is still in low-cost GaAsP, the action lies in high-profit, high-brightness LEDs and in colors not available three decades ago.

Monsanto leaves

Missing from today's action is one of the pioneers in the business, Monsanto. In 1979, perhaps tiring of a business that w as so different from the mature-business traditions of the Midwest, Monsanto sold its optoelectronics operation to General Instrument. In that year, MacLeod retired and went into the important business of growing wine grapes, which he does to this day.

General Instrument hired Ralph Simon as general manager of its new optoelectronics business. Simon left during the economic slump of 1984 and, in 1987, GI sold the operation to two private investors who had little experience in this type of business. They changed the company name to Quality Technology and ran it for two years, then got in arrears on interest payments.

GI came back into the picture and, in December 1989, brought back Simon as chief executive. Simon and some new investors bought out General Instrument, then later acquired Philips Optoelectronics and Harris Optoelectronics, which had been GE Optoelectronics, the pioneer in the optoelectronics business. In 1995, feeling that the name Quality Technology gave no clue as to its business, the company changed its name to QT Optoelectronics.

And everybody is marching forward to more colorful and brighter days.

Afegeix-hi un comentari: