So a while back I bought one of these on Taobao...

http://item.taobao.com/item.htm?id=8686679296

68 Yuan, which with the shipping and agents etc came to about $17 USD in a larger order, worth a punt. Subsequently I found that these are also sold on eBay http://www.ebay.com.au/itm/Soldering-Iron-Station-Temperature-Controller-For-HAKKO-936-T12-T1-T13-Handle-/170969190905?pt=LH_DefaultDomain_0&hash=item27ce8ed1f9&_uhb=1#ht_7058wt_1399

The Taobao seller also has a mini version of it, and sells built up in cases also...

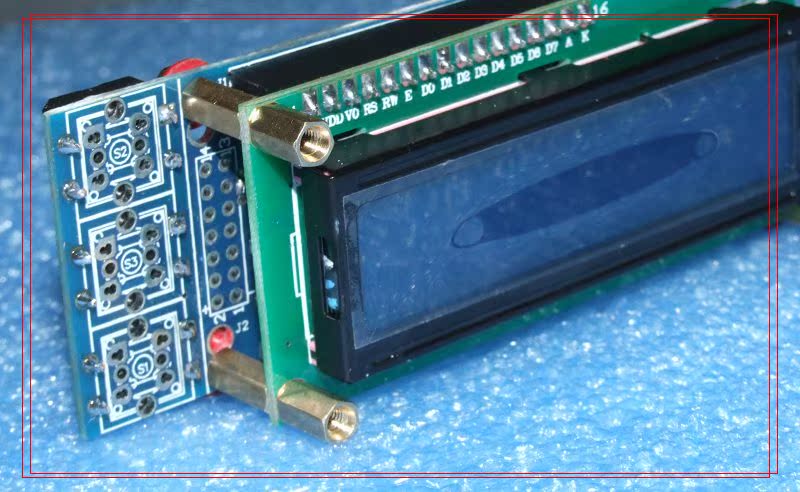

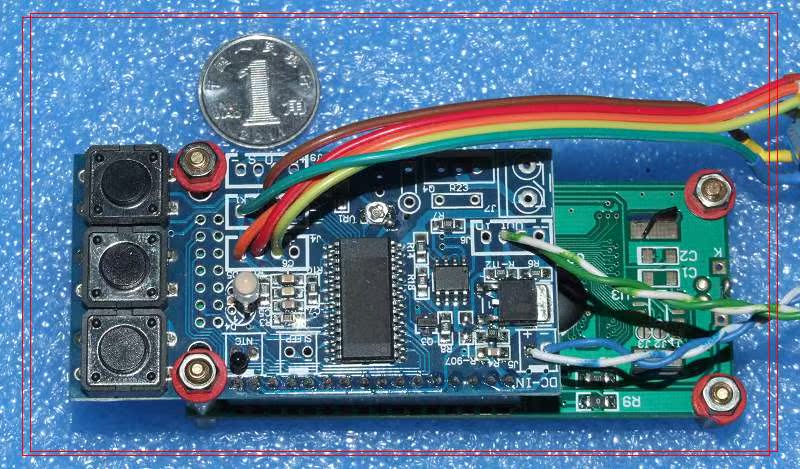

The silkscreen (and a display on the 1602 LCD) says it is "BG2001_V2" "By_LET".

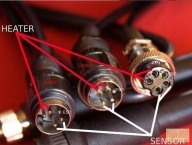

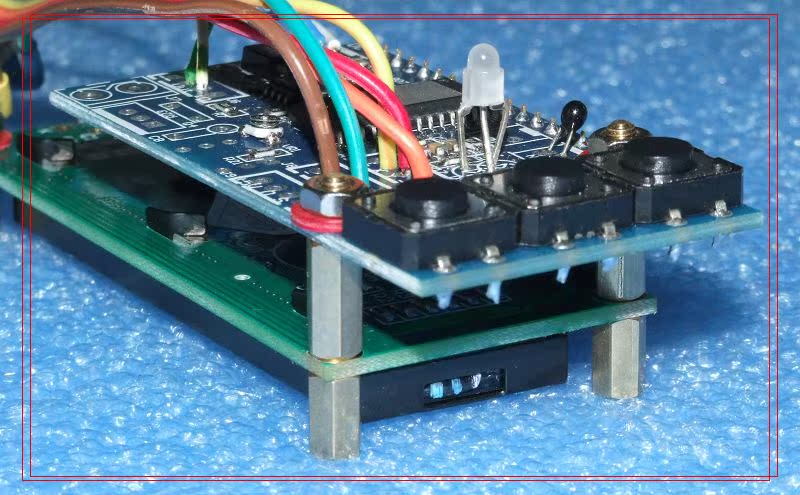

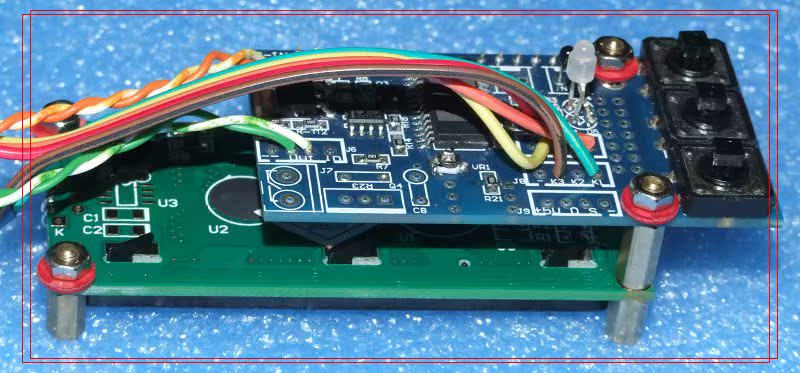

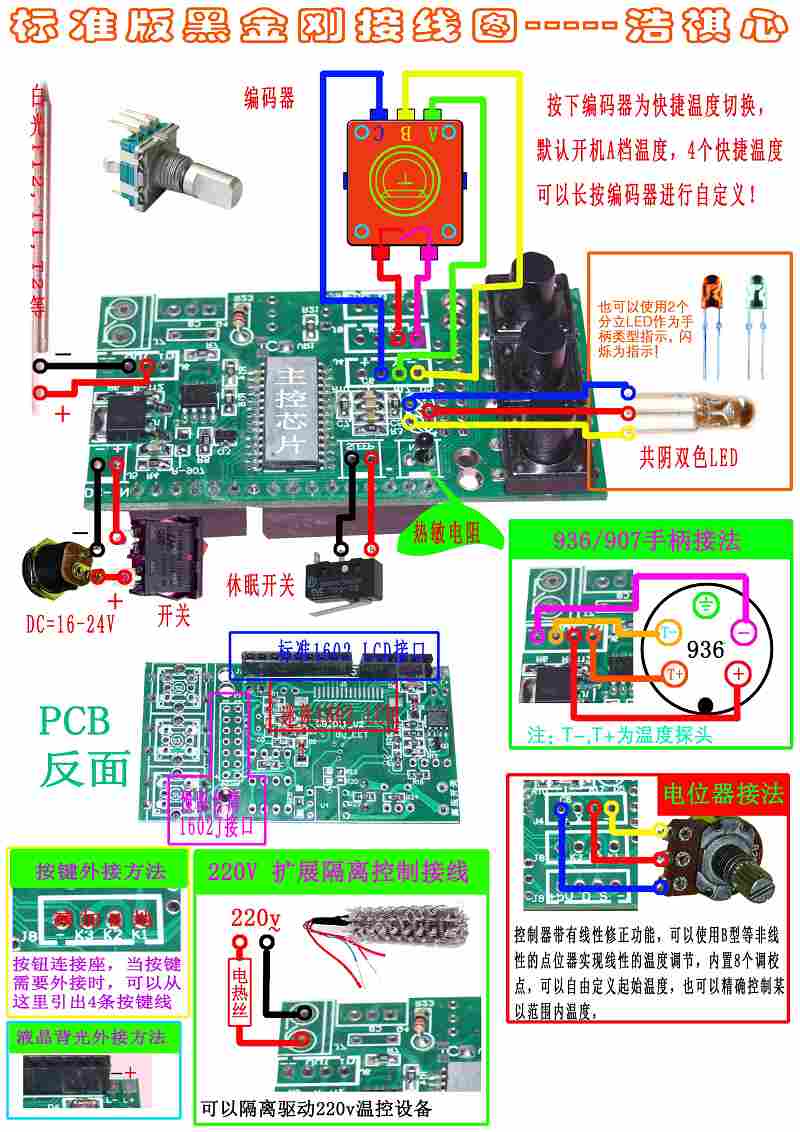

Anyway, supposedly (in so far as Google translate would allow) this supports standard Hakko 936 irons (and the T12 type which seem to be the most common in China for some reason), also supports 4 presets, automatic sleep, DC input in a wide range, input via encoderer or buttons. I have finally got around to wiring it up as best I can figure from the diagram. It detects a Hakko 907 handle as a 936 ok, and drives the element, unfortunately it just doesn't seem to be able to read the thermistor at all, the iron temperature readout seems locked to the ambient temperature (but the iron heats up in a matter of seconds, it's not a delay thing, the element is being driven flat out at 100% PWM).

It DOES know the thermistor is there, if I disconnect it, it reverts to T12 mode. I tried putting a pot in place of the thermistor connection and twiddling that flips between 936 and T12 mode around 300 Ohm I think (more becomes T12 and the iron temperature indication changes, less becomes 936 and the iron temperature display seems to lock to ambient [and drives at 100%]). So far as I know the handle's thermistor is working - at least, the resistance across it changes with the application of heat to the tip of the iron. I think the 907/936 irons are just a simple thermistor.

What I suspect, is that the controller simply doesn't support 936 handles (907 etc) properly, since it seems everybody in China uses the T12 based irons. All the images show T12 irons in use, none show 936. So yeah, a warning, if you want to use a Hakko 900 series handle, these controllers possibly don't work as best I can figure, despite what they sellers say.

I guess it could be a configuration thing that has to be twiddled - if you hold the encoderer button when powering up you enter a config mode where there are 7 different options you can change, some of them I have worked out, but some are just a number without any sort of notion was to what they do (if anything). So, if anybody has bought one of these (I see the ebay seller has flogged off a few of them) and had success with a 907 handle, please post below!