Hi Folks..I purchased a Hobby King Yihua 936, obviously there are faults that most are fixed, but, looking at the transformer, there is no way it's more than 35~40VA.

My question, I am using this as a 2nd station and building a complete DIY 936 clone OEM PCB circuit and non OEM parts etc. I need suitable transformers, for these units. I read the 936 is ~ 60VA transformer, I can find a 50VA to fit the transformer mount posts (of the case) but suggest a 73~75VA unit (or even a 100VA) would be more suited.

I'm a cheap arsed but know the need to pay for a decent iron/tips/controller PCB and transformer so any advice welcomed (even considering buying a proper Hakko 907M iron, full price, but where?).

__________________________________

Also I'm assuming the Hakko 936 station is a 50VA transformer?

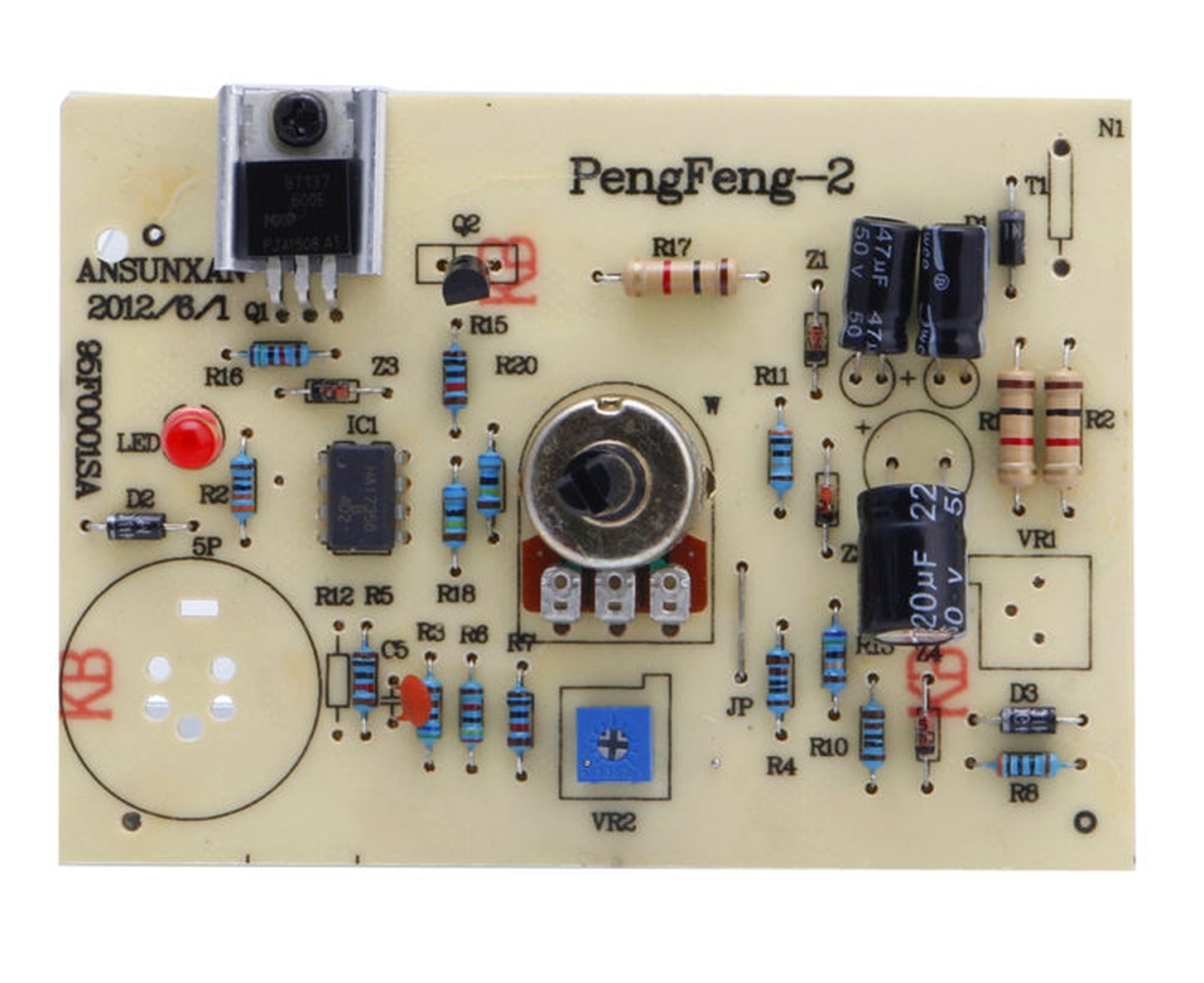

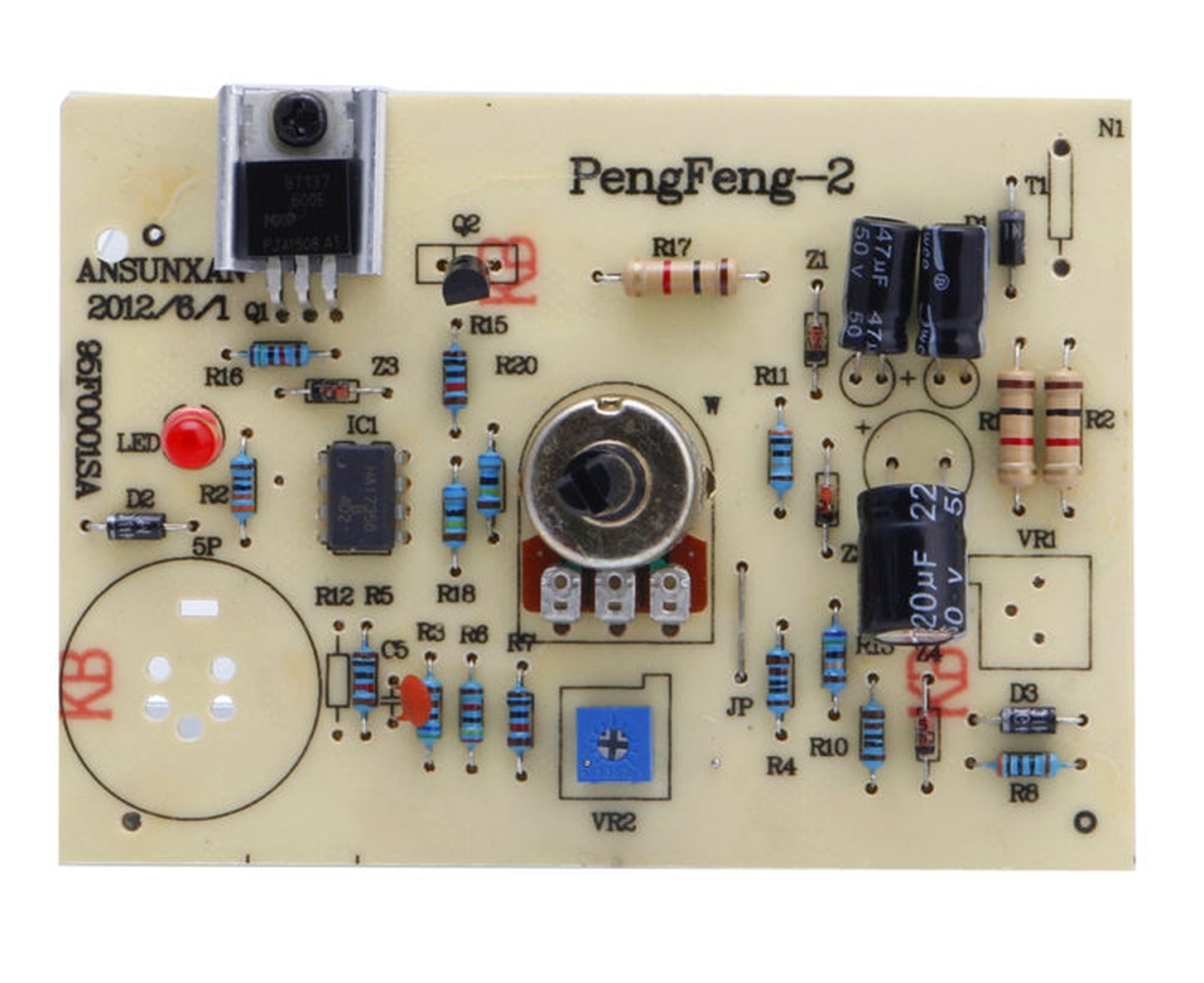

Finally.... Ok made some Hakko OEM copy PCBs and ordered a front panel and new case from fleabay as well as a host of parts, including new transformers. I now have a 936 station OEM copy ( although I'm using a 75VA 24V 2ndry transformer) and an original 907 iron (from RS) including a handful of OEM Hakko tips. Also changed the main power switch to a neon type and put in proper M205 cartridge fuses on this main switch, with a new sub PCB for this. Also put M205 cartridge fuse on the main PCB for 24V (transformer secondary) pwr to PCB. Cannot think for the life of me why Hakko didn't originally do this.

Also doing the "on power LED mod". Forgive my photographic skills!

This new system heats much much faster than the Yihua (25~30 secs or less with 3.2mm chisel tip) and has no problems doing big tasks and has much better thermal stability. Pretty much because the Yihua transformer was ~35VA! The Yihua heater tip is a nichrome wire in a ceramic tube and the ceramic end cracked on mine and is showing nichrome heater wire...barely ~1mm away from the tip metal (ground). Not good.

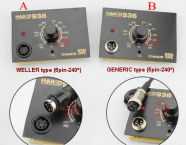

Also I found the Yihua uses a non std thermocouple temp feedback (mentioned before by others) which is not the same as the Hakko 907 iron PTC feedback. Funny enough I found a place in Aust selling very good copies of the 907 iron with the same ceramic heater and PTC feedback as the Hakko for ~$20, not bad indeed! Now I can change irons and keep calibration, I've ordered a thermocouple tip temp calibrator),

Just doing the 2nd station now but using a 50VA transformer for the 2nd one.

One for the safety inspectors..... my Yihua soldering station they wired the active/neutral wrong and switch/fused the wrong line. The Active (Line) was the blue wire, the Neutral (N) was the brown wire (it should be the other way round the moulded plug is made/wired wrong). The main switch also switched and fused this brown (Neutral) wire. At least the earth was correct! Safety standards......Ahhh yes China has a long way to go!

My question, I am using this as a 2nd station and building a complete DIY 936 clone OEM PCB circuit and non OEM parts etc. I need suitable transformers, for these units. I read the 936 is ~ 60VA transformer, I can find a 50VA to fit the transformer mount posts (of the case) but suggest a 73~75VA unit (or even a 100VA) would be more suited.

I'm a cheap arsed but know the need to pay for a decent iron/tips/controller PCB and transformer so any advice welcomed (even considering buying a proper Hakko 907M iron, full price, but where?).

__________________________________

« Reply #113 on: June 23, 2015, 06:08:58 PM »

Hakko 936 Schematic: http://dalincom.ru/datasheet/HAKKO_936_schematic.pdf

Ok purchased an original C1143 iron, Hakko 907, from RS components, plus some OEM tips, but noted the iron or packing does not state "ESD safe". Looking at the iron, its definitely Hakko but was wondering...is this iron indeed for their 936ESD stations or is it one of their older white version versions? The iron is white!Hakko 936 Schematic: http://dalincom.ru/datasheet/HAKKO_936_schematic.pdf

Also I'm assuming the Hakko 936 station is a 50VA transformer?

Finally.... Ok made some Hakko OEM copy PCBs and ordered a front panel and new case from fleabay as well as a host of parts, including new transformers. I now have a 936 station OEM copy ( although I'm using a 75VA 24V 2ndry transformer) and an original 907 iron (from RS) including a handful of OEM Hakko tips. Also changed the main power switch to a neon type and put in proper M205 cartridge fuses on this main switch, with a new sub PCB for this. Also put M205 cartridge fuse on the main PCB for 24V (transformer secondary) pwr to PCB. Cannot think for the life of me why Hakko didn't originally do this.

Also doing the "on power LED mod". Forgive my photographic skills!

This new system heats much much faster than the Yihua (25~30 secs or less with 3.2mm chisel tip) and has no problems doing big tasks and has much better thermal stability. Pretty much because the Yihua transformer was ~35VA! The Yihua heater tip is a nichrome wire in a ceramic tube and the ceramic end cracked on mine and is showing nichrome heater wire...barely ~1mm away from the tip metal (ground). Not good.

Also I found the Yihua uses a non std thermocouple temp feedback (mentioned before by others) which is not the same as the Hakko 907 iron PTC feedback. Funny enough I found a place in Aust selling very good copies of the 907 iron with the same ceramic heater and PTC feedback as the Hakko for ~$20, not bad indeed! Now I can change irons and keep calibration, I've ordered a thermocouple tip temp calibrator),

Just doing the 2nd station now but using a 50VA transformer for the 2nd one.

One for the safety inspectors..... my Yihua soldering station they wired the active/neutral wrong and switch/fused the wrong line. The Active (Line) was the blue wire, the Neutral (N) was the brown wire (it should be the other way round the moulded plug is made/wired wrong). The main switch also switched and fused this brown (Neutral) wire. At least the earth was correct! Safety standards......Ahhh yes China has a long way to go!