A clockwork mechanism is the fundamental organ or element of a watchmaking instrument (clock, pendulum, watch, etc.). Its main function is to "tell the time".

This mechanism is the result of a mechanical assembly of parts, some of which may have a movement in relation to the others. Referred to as the primary mechanism, it then includes other more elementary mechanisms, of lower levels, such as the driving element, the gear train, the escapement, etc.

It is the progress of the various watchmaking mechanisms that has enabled the evolution of watchmaking science. This practice has been included in the inventory of intangible cultural heritage in France since 2018.

Creation of a watchmaking instrument

The first true fully mechanical clocks date from the end of the thirteenth century. From that time on, the first of theN 1 of the clock is to "tell the time":

- or by an audible signal: ringing of bell(s) for example, especially on the first "blind" clocks without dials;

- either by a visual indication: hand(s) and dial;

- or by combining the two types of information.

To achieve this service function, "telling the time", the basic structure of the clock will remain more or less the same for centuries.

A brief technical analysis of the instrument makes it possible to visualize its layout and to determine the reference vocabulary usedN 2.

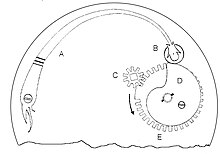

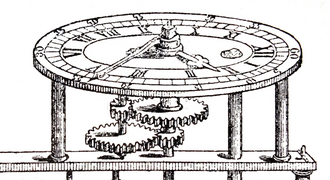

Analysis of the mechanism of a fifteenth-century foliot clock: Technical organizational chart.

Analysis of the mechanism of a fifteenth-century foliot clock: Technical organizational chart.

The building blocks of the mechanism that correspond to a technical function include:

- Movement: a device that brings together all the elementary mechanisms ensuring the regular movement of output to give the desired timeN 3either:

- the motor: a device that transforms the stored energy of a weight or spring into a "non-uniform" movement that is necessary for the system.

- Cogs: a set of gears that transmit the motor torque and the movement of the motor component to the other elements of the system. A distinction can be made between:

- the hour gear train, which transmits the movement to the escapement, helping to regulate the movement transmitted to the indicator hands;

- Other cogs: chiming gears, complication gears, etc.

- The oscillator (called regulator in the image above): a set that transforms the "non-uniform" movement given by the motor into a so-called "regular" movement of the system. It includes:

- the escapement consisting of a particular wheel, the escape wheel, alternately starting and stopping a suitable element (rod or anchor) which is linked to the oscillator;

- the resonator (called an oscillator in the image above), a kind of flywheel coupled to a hairspring, ensures the regularity and periodicity of the escapement's reciprocating movement;

- The cage (or frame): it receives and connects the different elements that make up the movement. On this framework are also grafted:

- the dial in front of which the hands will display the time;

- a possible striking mechanism that is more or less complex depending on the expected sound signalN 4.

The main elements will be discussed in the order in which they are presented, following their evolution succinctly.

The engine

The first clocks were weighted. Known since antiquity, this type of motor was used in the Middle Ages in the mechanisms for striking water clocks. It is mainly composed of a weight attached to a rope wound on a drum linked to the cog.

The function of this engine is to store potential energy when the weight is wound up and then to release it during its descent in the form of kinetic energy: the engine torque created will then transmit its driving force to the gear train.

Weight Clock

- Weight

It is originally made of stone, an economical material that can be worked easily. Its density is around 2,500 kg/m3. Used for several centuries, especially in building clocks, it was replaced, in miniaturized clocks such as wall clocks, weight clocks, comtoises, by weights made of cast iron, steel, lead, sometimes silver, whose densities were much higher (3 to 4 times more) and therefore took up less space.

-

-

Weight: one made of stone, the other of cast iron.

-

Movement Stone Weights; Cast iron bell weights.

-

Iron Parquet Clock Weight.

- The Rope

Originally a simple rope connecting the weight to the drum, it was replaced in the 19thcentury by a steel cable. In miniaturized clocks, cords, gut cords and chains will be more suitable1.

- The Drum

Drum and rope.

Drum and rope.

The cylinder is characterized by its diameter and length.

- The diameter around which the rope is wound must be compatible with the force to be transmitted to the gear: in the first building clocks, the friction to be overcome was important, hence weights of several tens or even hundreds of kilograms2 wound on large diameter drums;

- The length must allow the rope to be wound on a single line, so that its turns do not overlap, in order to obtain a constant driving force.

Counterweight Alarm Clock, Yellow: Hours; Red: ringtone.

Counterweight Alarm Clock, Yellow: Hours; Red: ringtone.

Diameter and length are directly related to the winding frequency. For example, if you have a 30 cm diameter drum that makes one turn per hour with a 3 cm diameter rope, and you want to rewind only once every 24 hours, the length of the drum should be more than 72 cm and the length of the rope should be 25 meters. This constraint of rope length partly explains the high location of building clocks and the full-time service of a "clock governor" responsible for winding and maintenance.

To gain length on the line stroke, it was of course possible to increase the frequency of winding or "to use a pulley that reduced the trajectory of the weight by half, but [sometimes] required the presence of a second weight"1 ; The engine weight must then be doubled to achieve the same effect.

In the twentieth century, the winding of the weight was  automated. This is the case, for example, with the astronomical clock in Bourges, which was automated in 19943.

In the miniaturized clocks of the modern era, such as the Comtoises, the driving weights of the movement and the striking are sometimes linked to the gears by grooved pulleys and not by drums. The system then imposes a counterweight to keep the cord in the groove of the pulley.

The winding of the weights, whatever the solution envisaged to drive the gear train, requires a small mechanism - often a ratchet - which allows the movement of the motor organ in one direction only, the direction of winding. The manual winding effort is transmitted to the system either via a capstan linked to the drum in the first clocks or by a crank. For the lightest weights, in the Comtoises for example, a key may suffice; In the pulley system, the winding action will be carried out by acting on the counterweight.

Spring clocks

Even before the fifteenth century, the mainspring appeared, which allowed the miniaturization of the clock.

This spring is wound inside a case, the barrel. When it is released, it will indirectly transmit the driving force to the geartrain.

- The mainspring

This "flat spiral" type spring was originally made of hardened, tempered and blued steel, and later became made of high-strength treated steel of the cobalt (Co), chromium (Cr) or nickel (Ni) alloy type. It is calculated for a minimum winding frequency of 24 hours4,5.

In its first uses, the motive force generated is not constant, it decreases irregularly as the disarming progresses6. To overcome this drawback, a "fusée" attached to the barrel will be used.

-

Insulated, "relaxed" mainspring.

-

Clock mainspring used without barrel.

- The barrel

- In modern watches, the¬†barrel is a "wheel formed by a circular toothed disc and a cylindrical case closed by a lid. It rotates freely on a shaft and contains the mainspring, which is attached to the barrel by its outer coil, and to the shaft by its inner coil. The barrel meshes with the first pinion of the watch gear train; It rotates slowly and its angle of rotation per hour varies between one-ninth and one-sixth of a turn7.¬†¬Ľ¬†;

-

Motor spring in its barrel.

-

Interior view of the mechanism.

-

Exterior view of the engine barrel.

-

- In the old fusee mechanisms used until the beginning of the¬†nineteenth century, the barrel was smooth. The rocket, a conical coil, received a gut rope - or, in the¬†seventeenth century, a steel chain - which wound in a helical groove on its periphery. This rope encircled the smooth barrel and connected it to the rocket. "Thanks to this, a more constant engine torque was obtained: the pull of the rope was exerted on the smallest diameter of the fusee at the beginning of the disarming, on the larger one when the spring was almost relaxed8. ¬Ľ. As the manufacture of springs improved, this fusee system was dispensed with, and further improved by stopping9, the constancy of the transmission of the driving force by limiting the travel of the spring to its optimal rebound phase.

-

Former barrel and fusee mechanism.

-

-

Barrel-fusee link by chain.

-

Another mechanism used before the appearance of the rocket by German watchmakers is the stackfreed10, which slows down the movement of the spring. Its disadvantage was its consumption of motive energy when braking11.

Stackfreed

Stackfreed

The Nuts and Bolts

Cogs are gear trains that transmit motor torque and movement from the motor component to other elements of the mechanism12.

A gear consists of a wheel and pinion mounted on different axes; If a sprocket and a wheel are mounted on the same axis, it can be called mobile.

-

A classic gear with spur teeth.

-

-

The first is mobile: wheel and pinion side by side.

-

A second mobile: wheels and arbral sprockets.

Gears have been known since ancient times. The famous Antikythera machine dated to the year 87 B.C. bears witness to this; Gears with triangular teeth were already integrated into this complex mechanism, which even included a differential gear13.

In watchmaking, the teeth of the wheels can be of different types; On the gears of building clocks, the profile went from a triangular shape to other more elaborate ones, determined by trial and error, then, in the seventeenth and eighteenth centuries, to more scientific profiles: the epicyclic profile and the involute profile of the circle allowing transmission by bearings, therefore without slipping and theoretically without friction14.

Epicyclic tooth profile.

Epicyclic tooth profile.

Each gear train element is made from specific materials:

- The Wheel

The wheel is the element with the largest diameter. Originally made of iron, then steel, these metals have often been replaced by brass or, better, bronze, alloys that are less oxidizable and have less friction.

- The Sprocket

This is the designation of the small diameter wheel in a gear. It spins faster than the wheel. Because of this, it tends to wear out faster. The sprockets were therefore made, most often, of iron and then of treated steel to compensate for this wear. There is an exception to the use of the above-mentioned materials: the wooden gears of clocks made in the Black Forest and sometimes in Spain.

A gear with a spindle pinion, also known as a lantern gear.

A gear with a spindle pinion, also known as a lantern gear.

In watchmaking, meshing ratios are important: for example, between the hour and seconds display there is a ratio to be obtained of 1/3600. This involves the construction of sprockets with as few teeth as possible (for sprocket teeth, the profession also says wings).

- An old solution was to use so-called lantern or spindle pinions: in this type of pinion, the teeth are replaced by cylindrical rods called spindles fixed between two flanges. The number of spindles can be reduced to a few units without affecting the meshing. It is recommended to choose mild steel for the spindles, it is a deliberate choice for maintenance at a lower cost: in fact, it is preferable to change this type of sprocket which will wear out quickly rather than the large diameter wheels meshing them14 ;

- The other solution is to use teeth with an epicyclic profile. Involute gears are incompatible with a high meshing ratio: the minimum number of teeth on a pinion must be thirteen, or better eighteen, to avoid interference15.

- Axes

The shafts, known as "shafts" for shafts with a large diameter in relation to their length, receive the sprocket. The materials used throughout the ages have changed from iron to treated steels for obvious reasons of resistance. Their cylindrical or pivot-shaped ends16 are supported by bearings or bearings integrated into the cage structure.

Hour cog, timer

The first clocks, with a simple mechanism, had only an "hour cog".

At the ends of this cog were:

- On the one hand, the last wheel of the train: the meeting wheel or crown wheel. This particular wheel is the functional link to the motion regulation system that will be referred to here as the "regulator". This meeting wheel will be considered later as an element of the technical "regulator" function;

- On the other hand, at the other end of the train, the "indicator" element is reduced to its simplest expression, i.e. a hand moving in front of a dial.

In more modern clocks and watches, the basic cog is the "minute cog"; It transmits the movement to the timer17, a secondary gear train placed under the dial, which communicates the rotation of the minute pinion to the hour hand.

- Timers

-

Minute gear train (in yellow) and minute track (in purple) for the hours.

-

Simulation in the movement.

-

Another configuration, perspective view.

Gear ratio

In a single gear train, the gear ratio18 is equal to the product of the number of teeth of the driving wheels divided by the number of driven wheels.

ÔŅĹÔŅĹÔŅĹÔŅĹ=‚ąŹÔŅĹLeading Men‚ąŹÔŅĹConducted

With:

- ÔŅĹÔŅĹ

and ÔŅĹÔŅĹ

and ÔŅĹÔŅĹ respectively the angular velocities at the input and output of the gear train;

respectively the angular velocities at the input and output of the gear train;

- ‚ąŹÔŅĹLeading Men

, the product of the number of teeth of the driving wheels;

, the product of the number of teeth of the driving wheels;

Detail of the minute track of the Huygens clock.

Detail of the minute track of the Huygens clock.

- ‚ąŹÔŅĹLed

, the product of the number of teeth of the driven wheels.

, the product of the number of teeth of the driven wheels.

- Simple example

In the minute track of the Huygens clock, taken up by Bion (see above), which communicates the rotation of the minute pinion to the hour hand, we have:

- the driving wheels: a and c with Za = 30 and Zc = 6;

- the driven wheels: b and d with Zb = 30 and Zd = 72.

The gear ratio is (30 x 6) / (30 x 72) or 1/12 which corresponds well to the fact that The hour hand makes one turn of the dial while the minute hand makes twelve.

Other cogs

Other gears may be involved in the movement, particularly in watchmaking instruments with complications: clocks, pendulums, watches where indications other than hours, minutes and seconds are displayed, such as the date, the diurnal movement of the Sun, the phases of the Moon, the zodiac, etc.

Schéma d'époque de rouage de complication pour le mouvement du Soleil, ca. 1446.

Schéma d'époque de rouage de complication pour le mouvement du Soleil, ca. 1446.

Le rouage de sonnerie, autre rouage particulier, sera intégré, plus loin, dans le mécanisme de sonnerie.

Le régulateur

Le mouvement d'un mécanisme d'horlogerie simple comme une horloge à poids, comporte trois éléments : le moteur, le rouage et le régulateur19,1.

Sans régulateur, la descente du poids moteur est un mouvement rectiligne uniformément accéléré. Il sera transmis au rouage sous forme de mouvement circulaire uniformément accéléré, mouvement ne convenant pas à l'indication régulière des heures.

La fonction ¬ę¬†r√©gulateur¬†¬Ľ va rendre le mouvement du rouage p√©riodique et assez r√©gulier pour √™tre consid√©r√©, √† l'Ňďil comme¬†circulaire uniforme. Ce sera l'invention qui correspondra √† la naissance de l'horloge m√©canique √† l'aube du¬†xive si√®cle.

The regularization of the movement is obtained from two intimately related elements: the escapement and the oscillator20,21 that have evolved together.

- the escapement transforms the driving energy of the small successive movements of the circular movement of the gear train into alternating impulses on the oscillator;

- The oscillator, a kind of flywheel, ensures regularityN 5 and the periodicity of the movement of the escape wheel. This organ is most often adjustable to play on the duration of the oscillations, a fraction of time involved in the choice of meshing ratios. The purpose is for the hour hand to make a revolution in n periods of oscillation.

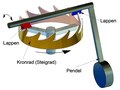

Foliot regulator: R + V escapement ( (emerald green), F oscillator (meadow green).

Foliot regulator: R + V escapement ( (emerald green), F oscillator (meadow green).

The foliot regulator

It is the first recognized regulator, first described in 138522 and used for more than six centuries. It is composed of three elements:

- the meeting wheel R: the last wheel of the hour gear, it has an odd number of teeth. Their saw-shaped profile alternately meets the pallets of the rod during movement;

- the V-rod: this is the exhaust system. This rod, with its two paddles, will transmit the movement of the meeting wheel towards the foliot: the upper paddle in one direction, then the lower pallet in the other direction, thus creating the oscillations of the regulator23. To have an alternating drive action and escapement, the vanes must have an angle of about 90¬į between them. The transmission of the movement had a disadvantage: the sudden change in the direction of rotation under the action of the paddles caused blows in the foliot; This was remedied by connecting the upper end of the rod to a gallows by an elastic coupling: pig's bristles or leather lace24 ;

- foliot F: mounted perpendicular to the end of the rod, it is composed of two arms acting as a flywheel. Two weights, also known as "regulated", adjustable in position on the arms of the rod, make it possible to increase or reduce the moment of inertia, and therefore the amplitude of the oscillations, which will thus affect the delay or advance of the clock.

The accuracy of this type of controller, according to the authors, was in the range of half an hour to an hour per day24,25. However, this variability has never been found by measurement N 6.

The Exhaust

The escape mechanism can be considered, for the purposes of study, as consisting of:

- the escape wheel, the last wheel of the gear train, with a particular tooth adapted to each type of escapement;

- the escapement itself, an element that maintains the oscillations of the regulating or oscillating organ.

"There are as many escapements as there are famous watchmakers!" exclaimed Jean-André Lepaute in 1755. Louis Moinet's engine, invented in 1816 and still functional and preserved today in Saint-Blaise (NE), beat at 216,000 vibrations per hour, making Louis Moinet the inventor of High Frequency in terms of escapement.

Today, there are more than 2,500 of them, which can be grouped into families. These include: the rod escapement, described above, which will adapt to different types of oscillators, the lever escapement, the cylinder escapement, the lever escapement, the pin escapement, etc.26,27,28.

The Oscillator

There are only three types of oscillators or regulating organs: the foliot, the pendulum, and the pendulum.

- The Foliot29 has been described previously in the "regulator" section;

- the clockwork pendulum, the result of Galileo's reflections in 1638, and concretized by Huygens in 1657. The first cycloidal pendulum clocks, invented by Huygens, had oscillations of large amplitude non-isochronouss (of the same duration). Isochronism was achieved by means of two cycloid-shaped blades against which the pendulum suspension wire rested during oscillation. Later, the amplitude of the oscillations is reduced, thus achieving isochronism without resorting to cycloidal cheeks30 ;

- The First Clocks

-

Galileo's Pendulum Clock Project, 1659 drawing.

-

Huygens' first pendulum clock, known as a pirouette clock, 1658.

-

Huygens' second clock, with cycloidal pendulum, 1673.

-

Seconds clock, described in detail, 1709.

-

Pendulum suitable for a lever escapement.

- The clock balance: watchmakers currently reserve the term balance wheel for the circular oscillator of watches, to avoid confusion with the clock pendulum, which is also traditionally called a balance.

There are about ten varieties31.

- Some types of pendulums

-

First pendulum? also known as crown foliot, Dondi, 1364.

-

Balance, simple steering wheel, with a rod escapement.

-

-

Balance-spring, scale, 1753.

-

Bimetallic or compensating balance.

-

Compensating balance wheel in situation.

The Cage

As its name suggests, it "encloses the entire mechanism of the different types of watchmaking instruments".

On the first clocks, whether indoor or building, its structure, generally parallelepiped in shape, is made up of an assembly of iron bars connected by corners, a kind of sloping keys. Later, these corners were replaced by dowels and bolts, but this type of skeleton lasted until the nineteenth century for building clocks. Later, at the same time, the cage was transformed into a cast iron frame for the so-called horizontal bell towers.

-

Wrought iron assembly wedge, ca. 1500.

-

Iron cage, with pegs, 1546.

-

Here, bolted and keyed elements, eighteenth century.

-

Cast iron horizontal clock frame, 1910.

-

Another cast iron building, twentieth century.

Brass will advantageously replace iron in miniaturized clocks, whether indoor or traveling. The structure of the latter will result from an assembly of plates connected by pillars32 ; Square, hexagonal in shape, it will also be adapted to the circular conformation of watches.

-

Iron lantern clock, ca. 1500.

-

Plates A and B and pillar Z in the Huygens clock, 1673.

-

Marine clock, mostly brass, 1763.

-

Watch with brass plates and pillars, 16th century.

One of the functions of the cage is to support the axes of the mobiles at their ends.

Originally, they were simple holes drilled in the plates or pillars, sometimes square in shape, in steeple clocks. Inserts, bearings or bearings33, will improve the axis guidance function. More precise, suitable for lubrication, especially by oilers34, they will be interchangeable. Initially made of steel or bronze, they were replaced in certain places on the watches by "stones"35 ", as early as the eighteenth century. These will be natural stones (garnet, agate, diamond) or synthetic stones (corundum, rubies), materials that reduce friction and thus reduce the wear of the surfaces in contact36.

-

Some brass or bronze pads.

-

Cylindrical pivot and stone-type bearing.

-

The so-called "conical" pivot and its stone counter-pivot.

The dial, the hands

Dial and hands are indicators. They make it possible to fulfil the main function of a watchmaking instrument: "to tell the time".

They are often presented together in a descriptive and artistic setting regarding a style of clock or watch. Here, only the historical aspect of these two elements will be developed.

The first clocks were blind, i.e. they had neither a dial nor a hand; they just ring. This audible information, which occurs only once an hour, at the "chime hour", will soon be supplemented by a continuous display, first by placing a fixed index in front of the graduated hour wheel, then thanks to the dial and hand pair. The dial, attached to or in front of the cage, has 24 time divisions and the hand is unique. This hand, attached to the end of the hour gear, does not have a fixed direction of rotation, it can rotate clockwise or retrograde. All of this took place before the 1400s37.

-

24-hour wheel of the Astrarium of Dondi[Which?]: it is 22 o'clock on the index (1348-1364).

-

24-hour clock of the Duomo of Florence with counterclockwise cipher (1443).

-

24-hour clockwise clock in St. Mark's Square in Venice (late15th century).

The evolution of clock faces was first reflected in a display on two times twelve o'clock, thus limiting the number of strikes, then in a twelve-hour turn of the dial, and even six o'clock in Italy.

In addition to indicating the time, the dial and hand combination will be able to provide other information corresponding to the various complications of the clock (the course of the Sun, the Moon, etc.). This multiple display was the result of astronomical clocks from the fifteenth century.

The¬†hour hand saw the appearance of its little sister, the¬†minute hand, before the end of the¬†sixteenth century, on an auxiliary dialN 7. After changing size, it joined the hour hand in the centre of the dial at the end of the¬†17th century, made by the English watchmaker¬†Daniel Quare in 1686N 8. It is interesting to note here that on the circumference of the dial, "the 'hour' interval is [theoretically] divided into four for one-hand clocks, and into five for two-hand clocks38.¬†¬Ľ

At the end of the 16th century, Tycho Brahe owned clocks that indicated the second of time. One of them had a wheel of 1200 teeth and a diameter of two cubits (about 80 cm))39but he was not much pleased with their accuracy; later, the seconds hand will appear, probably because of the application of the pendulum by Huygens around 1660-1673 and the needs of astronomy: in the years 1670-1680, in France, astronomers such as Jean Picard, Jean Richer, Dominique Cassini use pendulum clocks whose accuracy is given for a few seconds of time per 24 hours. It was first read with a pendulum in 1671, then on a secondary dial before 170940 and, finally, the second hand reached the centre of the dial in 173041.

-

Seconds wall clock by Bion, 1709.

-

Lepaute's parquet clock, ca. 1770.

-

Möllinger's central second hand clock.

From this time on, another hand will be able to indicate the dates.

The display considered here is analog. In the second half of the twentieth century, another type of indicator was introduced, the digital display, where the hands disappeared from the dial, which then only served as a frame.

The Ringtone

The first clocks were "chiming" exclusively. They indicated a particular time, such as the time of rising in religious communities. A few decades later, the innovation was to strike every hour with a number of strokes corresponding to the time given by the time mechanism. Advances, linked to the needs of users, brought complications to the basic ringing.

The following mechanisms can therefore be distinguished:

- the alarm clock, a relatively simple mechanism that occurs only once in the clock cycle;

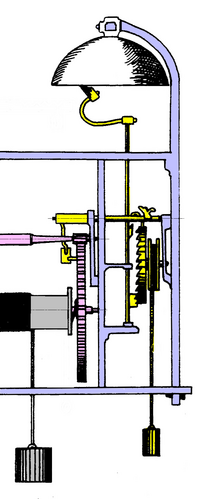

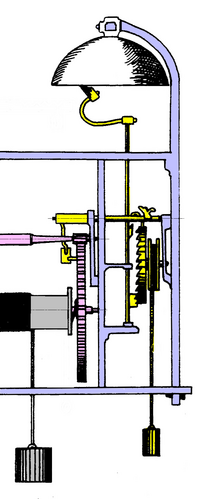

Alarm clock ringing mechanism.

Alarm clock ringing mechanism.

- the chiming of the hours, a more sophisticated mechanism that is implemented every hour with a counting of the strokes;

- complications which, as their name suggests, constitute complementary mechanisms, such as the striking of halves or quarters, repetitions, chimes, etc.

Whatever the chime intended, it is the hour gear train that triggers the striking gear train.

Alarm clock ringtone

This is the simplest and oldest type of ringtone. Unfortunately, sources are practically non-existent before the sixteenth century N 9.

- Description of principle

The striking mechanism (shown in yellow in the figure) is grafted onto the clock cage so that the clock's hour gear can trigger the mechanism. The latter has an engine weight and a rod escapement that will act on a striking hammer.

- On the hour wheel, a peg or peg serves as a trigger obstacle;

- it acts on the trigger lever linked to an axle which, when turning, will unlock the meeting wheel;

- The motor weight then drives the paddle rod at the end of which is a hammer that will strike a bell or alarm bell.

The exhaust system is not balanced, the engine weight is determined by trial and error so that the movement is not too accelerated.

If n pinions are placed on the so-called hour wheel, the engine can be triggered several times, provided that the engine weight is raised.

- Practical example

This alarm clock mechanism is borrowed from Diderot and d'Alembert's Encyclopédie, 176342.

- Alarm clock ringing mechanism

-

Front view of the alarm clock with its highlighted adjustment dial.

-

Striking mechanism only highlighted.

-

Simulation of the mechanism.

Summary Comments:

- The manual display of the alarm time is done by turning the alarm dial and placing the desired time in the rear extension of the hour hand; thus we play on the position of the peg X linked to the XZ piece, adhering to the "hour" wheel; X pulls the SR trigger;

- the arm T braces at rest against the ankle V linked to the meeting wheel;

- Lifting the trigger unlocks the meeting wheel, the motor weight kicks in and the chime is made43.

Striking of the Hours

It is linked to the invention of shot counting. The first clock to strike the hours was the Milan clock, dated 133644 ; There does not appear to be any technical documentation for it. One of the earliest surviving examples of this type of mechanism can be seen on the clock of Salisbury Cathedral, dated 1386 (see below).

Counting Wheel Ringtone

It is controlled by a wheel with notches, the spacing of which regulates the number of strokes struck.

- Description of principle

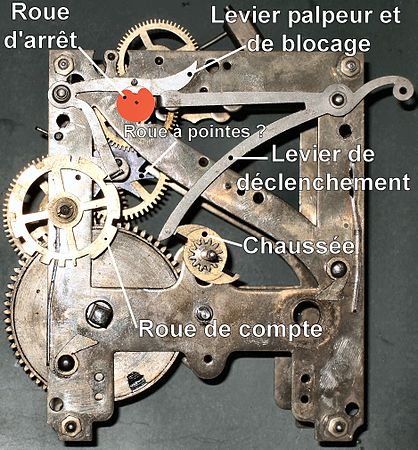

As with the alarm mechanism, the chiming of the hours is grafted onto the clock cage, in parallel with the movement, so that the clock's "hour" gear train can trigger the mechanism via the roadway45 acting on a trigger lever. This striking mechanism is composed of the same elements as the movement mechanism, i.e. a motor, a gear train and a regulator:

- The dedicated motor: weight on the first clocks, or later, mainspring. In the proposed diagram, this organ is not shown - it acts on the train at a different level depending on the type of watchmaking instrument;

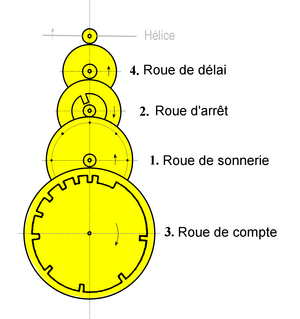

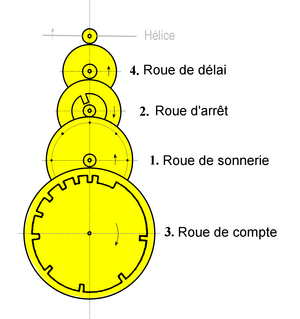

- The Ringer Cog46 which is a set of gears comprising wheels with specific functions; It most often includes:

- The striking wheel known as the "peg wheel" but also the wheel with pins, spikes or notches: during the rotation of the train, driven by the engine, each pin will act on the hammer lever to strike a single blow of the hours to strike

Ringing cog. ;

Ringing cog. ;

- The Stopping Wheel47 : it has an obstacle on its periphery (notch, notch, pin) which, by means of a locking lever, opposes the rotation of the train without the bell. When released, this lever is raised, allowing the train to rotate. One turn of the wheel corresponds to the pitch of the pegs on the previous wheel;

- The Account Wheel48 : it regulates the number of strokes struck; This is the key element in the striking of the hours. A probe lever attached to the locking lever is lifted out of its notch when triggered. The probe is then at the height of the outer diameter and slides over it during rotation. During this slide, it holds the locking lever in the up position despite the release lever falling. The length of the displacement on the outer diameter is determined to correspond to the number of strokes sounded by the striking wheel. When, at the end of the stroke, the probe falls into the next notch, the locking lever falls back and locks the drive wheel. The notches on the counting wheel and their intervals allow you to hit from 1 to 12 consecutive moves. If the road has two punches (one for every 1/2 hour), a slight modification of the notches on the counting wheel allows a strike to be struck every half hour.

- The Delay Wheel49 which, together with the stop wheel, has the function of releasing the striking gear train. On the other hand, it will quickly drive a brake propeller;

- The governor - this is the brake propeller: the approximate regularity of the movement of the landing gear is obtained by the mixing of the air caused by the rapid rotation of the propeller blades, also known as the flywheel or throttle. This simple system allows for a satisfying rhythmic rhythm of the knocks struck on the sounding element50.

- Counting Wheel Ring Mechanism

-

Simplified diagram of a mechanism.

-

-

Example on the clock of Salisbury CathedralN 10 (1386).

This type of chime can "count" (ring out of tune, i.e. without matching the display) when the hands are operated51. The counting wheel was used until the 1720s. Later, the chaperone appeared, having the same form and function, but with a different design (attachment to the barrel shaft)52.

1820 drawing of a clock built in Paris in 1379 by Henry de Wick.

1820 drawing of a clock built in Paris in 1379 by Henry de Wick.

Rake or rack and pinion bells

It is a bell in which the number of blows struck is regulated either by the position of a rake whose teeth operate the lifting of the hammer. On the Comté clocks, the rake is replaced by a rack. These two types of ringtones do not count.

- Summary Principle

Partial rake ring mechanism.

Partial rake ring mechanism.

The rake chime is triggered in the same way as the counting wheel chime: the pavement linked to the minute wheel will act every hour via a pin on the trigger lever bc. The latter will, among other things, raise the esse53 d attached to the small trigger a which will release the stop wheel; The striking mechanism then kicks in.

Snail.

Snail.

The striking of the hours is obtained from a cam, called a snail54, centred and oriented towards the hour wheel. The twelve o'clock to strike corresponds to the twelve sectors of this cam, in relation to the position of the hour hand; Thus the striking mechanism controlled by the hour hand does not count. On this cam, the probe g will allow the rake to be lowered when it is released by erasing the esse simultaneously with the release of the stop wheel: in position I on the snail, the rake descends by one tooth, in position III it descends by three teeth... up to twelve teeth in position XII. The descent of X teeth will allow you to hit X shots at X time.

This is the rake or comma lift55 s on the stopping wheel which will raise the rake of a tooth at each turn and which will control the strike with a blow of the hammer (mechanism not shown). When the rake is fully raised, the lever bc having been lowered, the esse tilts, stops the rake in the initial high position, and the lever a locks the stopping wheel by its pin h.

On the Comtoises, the rake is replaced by a rack; One particular site describes the striking mechanism in its entirety with its illustrations56.

"This chime comes to us from England, it was adapted to watches by Messrs. Edouard Barlow and Daniel Quare. In France, it was Honoré PONS who filed a patent for the "rake ringing for the clocks of Paris" in 1829.57.

Complications

They relate to particular indicators or sophisticated ringtones.

Notes & References

Notes

- ‚ÜĎ Today we would say the "main function"

- ‚ÜĎ The vocabulary of watchmaking is not standardized. From one author to another, and according to history, the designation of the constituent elements of a clock can vary somewhat. The basic vocabulary will find its references in¬†Emmanuel Poulle, historian of science of the¬†Middle Ages, who participated in the analysis and reconstruction of the¬†astronomical clock of Bourges, in the vocabulary of¬†Montres et horloges de Gr√ľnd as well as in the¬†Dictionnaire professionnel illustr√© de l'horlogerie and other works, all cited in the bibliography.

- ‚ÜĎ According to ISO, motion is a device that produces, maintains, and processes a periodic phenomenon capable of counting time. It can have sub-assemblies.

- ‚ÜĎ The envelope of the instrument (case, case, etc.) which is an element not directly involved in the function "Telling the time" is not taken into consideration here.

- ‚ÜĎ Hence its time-honored name in watchmaking: "regulator", but, in fact, it is the entire escapement+oscillator system that ensures the regularity of the gear train's movement.

- ‚ÜĎ A renowned watchmaker, professor at the¬†ENS de Lyon and watchmaker at the¬†Mus√©e du Temps in Besan√ßon, had rebuilt, after the year 2000, this type of foliot clock. He was surprised by its accuracy and reported on it in the magazine¬†ANCAHA. Sadly, he passed away, and this draft study was lost.

- ‚ÜĎ See below for the illustration of¬†Tycho Brahe's clocks in a book dating from 1598.

- ‚ÜĎ Nevertheless, an engraving in¬†Hevelius'¬†Machina coelestis, shown below and dating from 1673, shows different clocks, including one with a pendulum, which have two and even three different hands...

- ‚ÜĎ See an illustration of an alarm mechanism on an "archaic" hydraulic clock called¬†a drum clepsydra.

- ‚ÜĎ See the cue notes added to the image on Commons:¬†online access.

References

- ‚ÜĎ Revenir plus haut en‚ÄĮ:has b and¬†c Radko Kyncl 2001, p. 8.

- ‚ÜĎ For example, the motor weight of the clock (1920) in the church of St. Thomas, in Stadtbredimus in Luxembourg, weighs 80¬†kg;¬†ANCAHA 2015,¬†p. 51 n¬į 116.

- ‚ÜĎ Bougelot and Catoire 2006, p. 48.

- ‚ÜĎ Radko Kyncl 2001,¬†p. 10

- ‚ÜĎ Georges-Albert Berner 2002, "Spring".

- ‚ÜĎ Georges-Albert Berner 2002, "Disarmage".

- ‚ÜĎ Georges-Albert Berner 2002, "barrel".

- ‚ÜĎ Radko Kyncl 2001, p. 10.

- ‚ÜĎ Georges-Albert Berner 2002, "Stopping".

- ‚ÜĎ Georges-Albert Berner 2002, "stackfreed"; see also¬†Stackfreed

- ‚ÜĎ Collectif,¬†Tr√©sors d'horlogerie: Le temps et sa mesure du Moyen √āge √† la Renaissance, Palais des papes, Avignon, RMG, 1998,¬†119¬†p.¬†(ISBN 2-906647-30-6),¬†p. 22.

- ‚ÜĎ For gears, see the definition and the different types in¬†Georges-Albert Berner 2002, "gear".

- ‚ÜĎ Chavigny and Perissas 2009,¬†pp. 21-23

- ‚ÜĎ Revenir plus haut en‚ÄĮ:has and¬†b Chavigny and Perissas 2009,¬†p. 31

- ‚ÜĎ A. Chevalier,¬†Guide du dessinateur industriel, Paris,¬†Hachette,¬†coll. "Technique", 2001, 319 p.¬†(ISBN¬†2-01-168288-6),¬†p. 227; It's the ISBN printed on the book!

- ‚ÜĎ Georges-Albert Berner 2002, "pivot".

- ‚ÜĎ Georges-Albert Berner 2002, "Timer".

- ‚ÜĎ Georges-Albert Berner 2002, "cog" and "timer".

- ‚ÜĎ Chavigny and Perissas 2009, p. 26.

- ‚ÜĎ Radko Kyncl 2001, pp. 8, 14, 17.

- ‚ÜĎ Chavigny and Perissas 2009, p. 38.

- ‚ÜĎ Gerhard Dohrn-van Rossum 1997,¬†p. 51.

- ‚ÜĎ Radko Kyncl 2001, p. 15.

- ‚ÜĎ Revenir plus haut en‚ÄĮ:has and¬†b Chavigny and Perissas 2009,¬†p. 39.

- ‚ÜĎ Bougelot and Catoire 2006, pp. 21, 40.

- ‚ÜĎ Chavigny and Perissas 2009,¬†pp. 45-50.

- ‚ÜĎ Radko Kyncl 2001, pp. 15-17.

- ‚ÜĎ Georges-Albert Berner 2002, "Escapement".

- ‚ÜĎ The foliot is not an oscillator in the strict sense of the word, since it does not have its own period of oscillation, but the fact that it is "the seat of a periodic phenomenon" caused and maintained by a paddle rod may excuse this designation, which facilitates the categorical grouping used by certain watchmaking authors, such as¬†Radko Kyncl (trans. from the Czech).¬†Montres et horloges, Paris,¬†Gr√ľnd,¬†coll. "Encyclop√©die illustr√©e", 2001, 256¬†p. (ISBN 2-7000-1851-6).

- ‚ÜĎ Georges-Albert Berner 2002, "pendulum".

- ‚ÜĎ Georges-Albert Berner 2002, "pendulum".

- ‚ÜĎ Georges-Albert Berner 2002, "platinum"; "pillar".

- ‚ÜĎ Georges-Albert Berner 2002, "Pad".

- ‚ÜĎ Georges-Albert Berner 2002, "Oiling/Oiling".

- ‚ÜĎ Georges-Albert Berner 2002, "Pierre".

- ‚ÜĎ Radko Kyncl 2001, pp. 11, 13.

- ‚ÜĎ According to Emmanuel Poulle,¬†The Measurement of Time and Its History,¬†see the article online [archive] pp. 225-227.

- ‚ÜĎ Chavigny and Perissas 2009,¬†p. 64

- ‚ÜĎ Tycho Brah√©,¬†Astromiae instauratae mechanica,¬†1598¬†(read online [archive])), translated by¬†Jean Peyroux,¬†M√©canique de l'astronomie r√©nov√©e, Bordeaux, Bergeret,¬†1980,¬†p. 32

- ‚ÜĎ Nicolas Bion,¬†Treatise on the Construction and Principal Uses of Mathematical Instruments, The Hague, 1709-1723¬†(read online [archive])), p. 248.

- ‚ÜĎ Marie-Christine de La Souch√®re,¬†Une histoire du temps et des horloges, Paris, ellipses,¬†2007, 169 p.¬†(ISBN 978-2-7298-3555-2), p. 84.

- ‚ÜĎ BnF, Gallica, Horlogerie [archive].

- ‚ÜĎ See description in Encyclopedia:¬†Online Access.

- ‚ÜĎ Gerhard Dohrn-van Rossum 1997, pp. 113, 137.

- ‚ÜĎ Pinion that controls the timer; the roadway makes one turn in 1 hour¬†Georges-Albert Berner 2002, "causeway".

- ‚ÜĎ Georges-Albert Berner 2002, "Cog".

- ‚ÜĎ Georges-Albert Berner 2002, "Judgment".

- ‚ÜĎ Georges-Albert Berner 2002, "Chaperon".

- ‚ÜĎ Georges-Albert Berner 2002, "Delay".

- ‚ÜĎ A detailed article on this mechanism exists in "translatable" German in Wikipedia:¬†Schlagwerk (Uhr)

- ‚ÜĎ Georges-Albert Berner 2002.

- ‚ÜĎ On this subject, see the article by Andr√© Lemaire in the journal¬†ANCAHA 2015, p. 45-50 n¬į 109 and p. 70-71 n¬į 112.

- ‚ÜĎ Georges-Albert Berner 2002, "esse".

- ‚ÜĎ Georges-Albert Berner 2002, "Lima√ßon".

- ‚ÜĎ Georges-Albert Berner 2002, "comma".

- ‚ÜĎ See Michel Dumain's website¬†DIS MOI COMMENT √áA MARCHE UNE SONNERIE DE COMTOISE, online access [archive]

- ‚ÜĎ See the page¬†Some notions of watchmaking on the website of the Mus√©e d'horlogerie d'Aliermont,¬†online access [archive]

Annexes

Bibliography

: Document used as a source for this article.

: Document used as a source for this article.

Radko Kyncl (trans. from Czech),¬†Montres et horloges, Paris,¬†Gr√ľnd,¬†coll. "Encyclop√©die illustr√©e", 2001, 256¬†p. (ISBN 2-7000-1851-6).

Radko Kyncl (trans. from Czech),¬†Montres et horloges, Paris,¬†Gr√ľnd,¬†coll. "Encyclop√©die illustr√©e", 2001, 256¬†p. (ISBN 2-7000-1851-6). Emmanuel Poulle,¬†The Measurement of Time and Its History,¬†see the article online [archive].

Emmanuel Poulle, The Measurement of Time and Its History, see the article online [archive]. Georges-Albert Berner, Dictionnaire professionnel illustré de l'horlogerie, Fédération de l'industrie horlogerie suisse FH, 2002 (read online [archive])). Access to Wikipedia: Illustrated Professional Dictionary of Watchmaking.

Georges-Albert Berner, Dictionnaire professionnel illustré de l'horlogerie, Fédération de l'industrie horlogerie suisse FH, 2002 (read online [archive])). Access to Wikipedia: Illustrated Professional Dictionary of Watchmaking. ANCAHA, Bulletin de l'association nationale d'horlogerie ancienne et d'art, Paris, 2015 max..

ANCAHA, Bulletin de l'association nationale d'horlogerie ancienne et d'art, Paris, 2015 max.. Alain Bougelot and Jean-Yves Catoire, The Astronomical Clock of Bourges Cathedral: Its History, Its Rehabilitation, Levet, J.-Y. Catoire, 2006, 80 p. (ISBN 2-9526232-0-1).

Alain Bougelot and Jean-Yves Catoire,¬†The Astronomical Clock of Bourges Cathedral: Its History, Its Rehabilitation, Levet, J.-Y. Catoire,¬†2006, 80¬†p. (ISBN 2-9526232-0-1). R. Chavigny and M. Perissas,¬†La mesure du temps √† travers les √Ęges: son art - sa technique, Toulouse, Ixc√©a,¬†2009, 306¬†p. (ISBN 978-2-84918-106-5).

R. Chavigny and M. Perissas,¬†La mesure du temps √† travers les √Ęges: son art - sa technique, Toulouse, Ixc√©a,¬†2009, 306¬†p. (ISBN 978-2-84918-106-5). Gerhard Dohrn-van Rossum (trans. from German), L'histoire de¬†l'heure : L'horlogerie et l'organisation moderne du temps, Paris, La Maison des sciences de l'homme,¬†1997, 464¬†p. (ISBN 2-7351-0741-8,¬†read online [archive])).

Gerhard Dohrn-van Rossum (trans. from German), L'histoire de l'heure : L'horlogerie et l'organisation moderne du temps, Paris, La Maison des sciences de l'homme, 1997, 464 p. (ISBN 2-7351-0741-8, read online [archive])).

Related articles

External links

On other Wikimedia projects:

![Roue des 24 heures de l'Astrarium de Dondi[Lequel ?] : il est 22 heures à l'index (1348-1364).](https://upload.wikimedia.org/wikipedia/commons/thumb/d/d3/Astrarium_Dondi_roue_des_heures.jpg/120px-Astrarium_Dondi_roue_des_heures.jpg)

![Exemple sur l'horloge de la cathédrale de Salisbury[N 10] (1386).](https://upload.wikimedia.org/wikipedia/commons/thumb/c/ce/Salisbury_Cathedral_2012_11_new1.jpg/300px-Salisbury_Cathedral_2012_11_new1.jpg)

Comentaris publicats

Afegeix-hi un comentari: