HEADLAMPS & HEADLAMP CIRCUITS

Although the 1968~79 VW 1600 & 17/18/2000 Type 2s, were never reknown as high-speed vehicles, they were always easily capable of exceeding the maximum safe night-time speed on unlit roads, associated with the effective illumination range, of the factory-fitted headlamps; both the Hella and Bosch replaceable-bulb units, used in Great Britain & Europe and the DOT standard, sealed-beam units, used in North America, which are allegedly even worse!

For RHD (i.e. right-hand drive) vehicles, which are driven on the left-hand side of the road (i.e. the United Kingdom, Republic of Ireland, Japan and most of the British Commonwealth; apart from a few territories, such as Canada and Mozambique - a former Portugese colony, in south east Africa), one requires RHD headlamps, which when supplied, factory-fitted to the vehicle, from Bosch or Hella, typically bore a label stating, "für links verkehr". On dipped beam, these headlamps are directed in an asymmetric beam pattern, towards the left-hand kerb.

Those with LHD (i.e. left-hand drive) vehicles, which are usually driven on the right-hand side of the road, normally require LHD headlamps, which when supplied, factory-fitted to the vehicle, from Bosch or Hella, typically bore a label stating, "für rechts verkehr". On dipped beam, these headlamps are directed in an asymmetric beam pattern, towards the right-hand kerb, unless one has North American, DOT-standard lamps, which have a different beam pattern.

http://www.rallylights.com/hella/Beams.htm

As these vehicles have aged, over the past few decades (1968~79 VW Type 2s, are circa 29~41 years old!), headlamp performance has probably deteriorated, as a consequence of the headlamp-unit reflectors progressively losing their high-lustre, mirror finish (i.e. reflectivity) and the decreasing available voltage, owing to increasing electrical resistance of the wiring loom. An additional factor, is the decreasing transparency, of a conventional bulb's glass envelope or sealed-beam unit's outer lens, owing to the silvering effect, of the tungsten filament's evaporation and deposition process; which is particularly noticeable on many long-service bulbs.

New, high-lustre reflectors, typically reflect more than 90% of the incident light, whilst dull, oxidised surfaces, might reflect as little as 10%; reducing a headlamp's light output, to almost a tenth of what a new reflector would give. If a reflector surface has lost its lustre, refurbishment might be possible, by recoating the surface, but it is usually only practical or economical, to replace the complete lamp unit, sealed-beam unit or separate reflector.

Unless electrical cables have corroded internally (not usually a problem, except in a few isolated, extreme cases!), the significant increase in the wiring loom's resistance, is attributable solely to oxidation of the connections; although oxidised and/or burnt switch and relay contacts, might also make some contribution..

Current for the headlamps, flows around a complete circuit, from the positive to negative connections of the generator (i.e. dynamo or alternator), via the main-supply & secondary cables, ignition switch, main light switch, fuse box, headlamp dip & flasher relay (i.e. dimmer relay, in USA parlance), headlamp units, steel bodywork, engine crankcase & transaxle case and the transaxle-to-bodywork, braided earth strap (i.e. ground cable, in USA parlance); involving a large number of separate connections.

Reductions in the nett voltage available to the headlamps, for whatever reason (i.e. generator output and/or resistive losses in the wiring loom), cause a much greater reduction in light output, than one might expect! This occurs because power consumed is proportional to voltage squared (i.e. P = V²/R) and a lower proportion of the consumed power, is emitted as visible light, owing to reduced bulb-filament temperature (see university physics text books, for a full explanation of Wien's Displacement Law and Planck's Law, re "black-body" radiation).

Assuming a typical generator supply voltage of 13•5V when under load, the following table summarises the effect of reductions (or increases, associated with greater generator output!) in the available nett voltage to the headlamps:

Applied Voltage (V) 11•48 12•15 12•83 13•5 14•18 14•85 16•2

Applied Voltage (%) 85 90 95 100 105 110 120

Relative Light Output (%) 53 67 83 100 120 145 200

It seems incredible, but reducing the headlamps' available nett voltage from 13•5V to 11•5V (a reduction of just 2•0V or 15%), virtually halves the headlamps' light output. This is why it is important to minimise voltage losses in the electrical circuit and to maximise the generator supply voltage as far as practical, but not exceeding the 12-volt, lead-acid battery's maximum charging voltage of 14•4V, as stated by manufacturers.

Apart from the few screw-thread & ring-terminal connections of the generator and various earth straps & cables, which might need periodic cleaning with a mild abrasive (e.g. fine wire wool or "wet & dry" silicon carbide paper) and water-proofing (e.g. petroleum jelly, copper grease or battery-terminal grease) the remaining connections comprise crimped male & female blade connectors. Not only is there oxidation of the contact surfaces between the connectors, which can be similarly cleaned (sometimes also needing fine-toothed, needle-files), but also where the cable's wire filaments are crimped to the connector.

If the crimped portion is only slightly discoloured, electrical resistance can be reduced by lightly soldering, so that solder only penetrates into the crimped, unsleeved portion, of the cable's wire filaments. The solder will not penetrate, if the joint is highly oxidised and/or greasy; in which case the joint must be uncrimped, degreased and/or acid-cleaned, rinsed, dried and reassembled, after which it can be soldered, as previously described.

Additional strain relief of soldered joints is also desirable, because being brittle, they are more prone to breakage; including the long-term effects of vibration. To minimise renewed oxidation of the connections, it would be advisable to inhibit the ingress of moisture, by use of one or more of, terminal grease, silicone sealant, self-adhesive PVC tape, hot-melt adhesive with shrink sleeving (as used on modern cars) or other methods.

These remedial measures, will restore the standard headlamp system, to the modest perfomance that existed, when the vehicle was new, or at best, provide a marginal improvement on that. To make any significant improvement over the original, as-new system, one really needs to upgrade the headlamp system specifications.

If one's existing headlamp units, are of the type with 45/40W R2 glass-envelope bulbs, then provided the reflectors still have a good mirror finish, one can simply substitute at very modest cost, a pair of P45t flanged, 60/55W H4 quartz-halogen bulbs, which give a vast improvement in headlamp performance, without making any modifications. This is what I did in summer 1976, about 32 years ago, with my family's then recently acquired, second-hand, British specification, 1973 VW 1600 Type 2 Westfalia Continental campervan. H4 bulbs have an integral, black filament-shield, so if practical, it might be worth removing the redundant bulb shield, from the headlamp reflector, which would otherwise cut off a small portion of the light output.

Picture of P45t & P43t flanged H4 bulbs

http://www.thesamba.com/vw/forum/album_page.php?pic_id=338649

However, if one has sealed-beam headlamp units, as were the norm in North America, or post-1973 VW Type 2 headlamp units with dulled reflectors, then it will be necessary to replace these with either North American, DOT specification tungsten-halogen sealed-beam units (said to be a far from ideal option and probably illegal outside North America!) or prefererably, dedicated H4 headlamp units (lack redundant bulb shields), with P43t flanged, 60/55W H4 quartz-halogen bulbs, as manufactured by Bosch, Hella, Lucas, Marelli, Stanley, Valeo (i.e. Cibié or Marèchal), Wipac and other companies. Bosch and Hella lamps are usually direct replacements, but with products from other manufacturers, one might need additional mounting hardware.

http://www.s-v-c.co.uk/prod/wipac-quadoptic.html

An unusual three-section headlamp unit (Item No. KL-013), which combines an H4 headlamp, H3 long-range lamp and direction indicator into a single unit, is available from Brazilshopping.com. At present, it's of unknown manufacture and thought to be only for countries, in which one drives on the right. Costing a modest US$39•99 (i.e. about £20) per pair, excluding bulbs, the quality and E-mark or DOT-standard compliance, is open to question, but components manufactured in Latin America, are generally of low cost and note that a pair of British, Wipac Quadoptic headlamp units, are typically only about twice this price.

Two models of three-section headlamp units, having a similar appearance, are available from the Mid America Motorworks, in Effingham, Ilinois, USA, priced at US$99•99 (i.e. about £50) per pair, including bulbs. They (Part Nos. 303-101 or 303-091) combine an H4 headlamp, a 4W parking light (i.e. side-light) and either a clear H3 long-range lamp or an amber H3 fog lamp, into a single unit. The commonly used power rating for H3 quartz halogen bulbs, is 55W, but bulbs of 100W power rating, are also readily available.

http://www.mamotorworks.com/acvw-5-169-3305.html

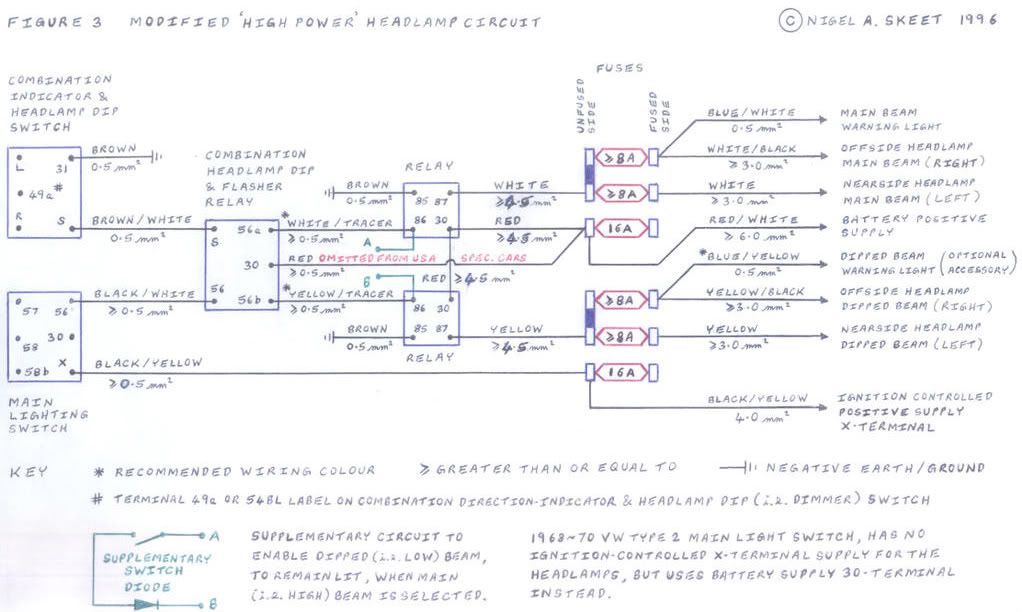

These days, there are also P45t & P43t flanged, Xenon enhanced, 60/55W H4 quartz-halogen bulbs, which are claimed to be brighter still. It is possible to further upgrade the headlamps, by using higher power H4 bulbs, such as 70/65W, 85/80W, 100/55W, 100/80W, 100/90W, 130/90W, 130/100W & 160/100W, but it will be necessary to employ a revised electrical circuit, with heavy-duty cable and two or more accessory relays, which will avoid the possibility of the factory-stock cables overheating and maximise the voltage available to the headlamps by providing a more direct current path.

In 1988/89, I performed this further upgrade to my family's vehicle, using P45t flanged, 100/80W H4 bulbs (the highest power, then available for our existing lamp units) and 40A accessory relays; retro-fitting a dipped-beam warning light (supplementary to the main-beam warning light), which is quite useful under conditions where daytime dipped-headlamp use is either desirable or mandatory, as is the case in Canada and Scandinavia, plus an increasing number of other European countries. I have also since incorporated a switch and diode, between the headlamp dip & flasher-relay output terminals, so that if I desire, I can keep the dipped-beam illuminated, whilst main beam is selected, which is perfectly legal in the United Kingdom and is actually employed on some car marques.

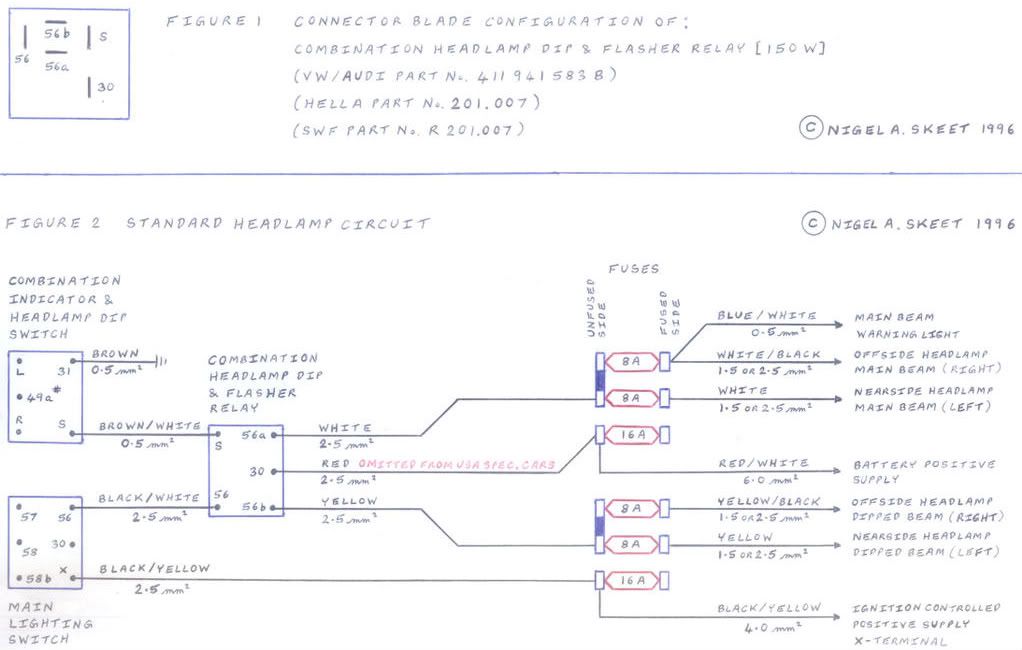

Electrical circuit wiring diagrams for both the 1968~79 VW Type 2, factory-stock circuit and the revised circuit, incorporating accessory relays

http://s275.photobucket.com/albums/jj287/naskeet/?action=view¤t=Headlamp-Circuit-1.jpg

http://s275.photobucket.com/albums/jj287/naskeet/?action=view¤t=Headlamp-Circuit-2.jpg

By reducing their associated current load, to almost nil, it also has the secondary benefit, of extending the lifespan of the ignition switch, main light switch and headlamp dip & flasher relay, for which it is becoming increasingly difficult, to find good-quality replacements, when and if these fail. In contrast, good-quality, 30A and 40A accessory relays, are readily available at modest cost. Hence, it might also be beneficial to implement this upgrade, with the relatively low-power headlamps, to both minimise voltage losses and extend component lifespans.

Normally, accessory relays can be plugged into the vacant positions of the 1971~79 VW Type 2, combined fuse & relay box, but if this is not an option, there are several other ways of mounting & connecting them, including plug-in, accessory relay boxes, or even moulded plastic, six-position, relay connector blocks, salvaged from Austin Montego or Metro cars, of which I have two mounted inconspicuously, beneath my 1973 VW Type 2, steering-column support bracket. I still have a few spare, for sale or barter.

Picture of the direction-indicator relay, headlamp dip & flasher relay and three accessory relays, mounted in the 1971~79 VW Type 2, combined fuse & relay box

http://www.thesamba.com/vw/forum/album_page.php?pic_id=327515

Pictures of six-position, relay connector blocks, alone and mounted beneath my 1973 VW Type 2, steering-column support bracket

http://www.thesamba.com/vw/forum/album_page.php?pic_id=327973

http://www.thesamba.com/vw/forum/album_page.php?pic_id=327969

This is the Vauxhall Cavalier Mk. 2 fuse cum relay box, which I adapted for use on my British specification, 1973 VW Type 2 Westfalia Continental campervan.

http://www.thesamba.com/vw/forum/album_page.php?pic_id=328147

There are as standard, eighteen positions for plastic blade-fuses and four of either turn-signal relay, accessory relays or buzzers. In addition, there are five bays beneath, into which one can slide clip-in modules of two types. One module type accommodates two plastic blade-fuses, whilst the other module type accommodates single relays, of various 1/4 & 1/8 inch blade-terminal configurations, as shown separately in the top two rows of images below.

http://www.thesamba.com/vw/forum/album_page.php?pic_id=327972

I adapted one of the two-fuse holder modules, to accommodate my VW headlamp dip & flasher relay, by cutting and heat welding into the module, the appropriate section of the VW Type 2 fuse & relay box, relay-connector strip.

Although it is technically possible, to upgrade any vehicle with high-power headlamps, the legality of doing so, varies according to country, plus the date on which the vehicle was manufactured or first registered. For example, in the United Kingdom, vehicles first used before 1st April 1986 (i.e. all 1968~79 VW Type 2s), are subject to a minimum power of 30W per lamp, on both main & dipped beams and the universal requirement that the headlamps should not cause undue dazzle to other road users.

The Filament Lamps for Vehicles (Safety) Regulations 1982, Statutory Instrument No. 444.

The Road Vehicles Lighting Regulations 1984, Statutory Instrument No. 812.

In contrast, vehicles first used on or after 1st April 1986 (i.e. about half the 1980~92 VW Type 25s - aka T3 or Vanagon), are subject to no explicit minimum or maximum power, but both the headlamp units and the bulbs fitted to them, must bear an appropriate E-mark, which might implicitly restrict the power ratings that may legally be employed, dependent upon the bulbs available. Of course, properly aligned headlamps cause minimal dazzle, so it's unlikely that any law officers or MOT inspectors, would seek to inspect the markings on one's headlamp bulbs!

Although the British & European, E-mark headlamps, with asymmetric beam pattern, are considered superior to North American, DOT-standard lamps, readers in North America would be wise to seek advice, from automotive lighting specialists, such as Daniel J. Stern, who have local knowledge about which lamp units may legally be used. There seem to be some light units which satisfy both European and North American regulations.

http://www.ibiblio.org/rdu/autoligt.txt

http://www.danielsternlighting.com

http://www.danielsternlighting.com/products/products.html

British & European and probably most other non-North American drivers, take for granted, the facility to flash the headlamp main beams on and off, without turning the headlamps on, at the dashboard-mounted, main light switch; the steering-column mounted, dip-switch (i.e. dimmer-switch, in USA parlance), acting like a non-latching, momentary switch, so that the main beam is illuminated, only whilst the switch-lever is depressed.

Strictly speaking, flashing the headlamps, has the same meaning as sounding the horn (i.e. warning other drivers of one's presence), which is useful on busy, noisy, high-speed roads, where a horn might not be heard or the origin of the horn's sound difficult to determine. Informally, flashing the main beam in the United Kingdom, is used to acknowledge a courtesy, signal to other drivers that one is allowing them to emerge from a road junction or driveway, or simply as a friendly greeting between fellow air-cooled VW owners.

Apart from the part numbers, the British & European headlamp dip & flasher relay (VW part No. 411 941 583B) is virtually identical in appearance to that of the North American headlamp dimmer relay (VW part No. 411 941 583C), for the 1971~79 VW Type 2s, except that instead of a brass locating lug, there is an additional 6•3 mm (i.e. ¼-inch) blade terminal, labelled 30, which is connected via a red 2•5 mm² cable, to a constant battery supply, at terminal-30 of the fuse box. Similar differences exist between headlamp relays, for the 1968~70 VW Type 2s.

Pictures of the British & European headlamp dip & flasher relay and the North American headlamp dimmer relay, for the 1971~79 VW Type 2, showing the similarities and differences

http://www.thesamba.com/vw/forum/album_page.php?pic_id=327513

It is solely this additional relay-terminal & cable connection, rather than a modified dip-switch, which provides the headlamp flashing facility. Hence, North American vehicles, can also have the flashing facility, simply by substituting the appropriate relay and making the additional cable connection, as a few of my e-mail pen pals in the USA, have already done.

Having high-power headlamps, it is important that they are extinguished, when the ignition is switched off. Owing to the starter-motor-interrupted, ignition-controlled supply (i.e. terminal X) to the main light switch, 1971~79 VW Type 2s do this automatically, but the 1968~70 model-years, do not have this facility, so one needs to ensure that their headlamps are switched off manually!

I envisage that it would be possible, to mimic the later models, by slightly revising the main electrical supply circuit, substituting a later-model, main light switch, in combination with two relays, to create a starter-motor-interrupted, ignition-controlled supply. This supply can also be used for other high-current loads (e.g. windscreen wipers, heated rear window & heated front windscreen), which is automatically interrupted when the starter motor is operated, maximising available battery voltage & current, to restart the engine if one inadvertantly stalls.

_________________

Regards.

Nigel A. Skeet

Technical Editor & Sometime Editor

Transporter Talk magazine

Volkswagen Type 2 Owners' Club (Great Britain)

http://www.vwt2oc.net |

|